Enhance Your Home’s Curb Appeal with Decorative Architectural Keystones

Add some chic and fashion to the exterior of your house: make it attractive and memorable! Make your house stand out from the crowd: add individuality and distinctive accent, take advantage of the Decorative Architectural Shapes Keystones. If you care about the look of your house you may wish to add Decorative Architectural Shapes Keystones or other decorative architectural elements that will refresh the look of your property. Use your imagination and take advantage of our useful tips while choosing the practical and elegant Decorative Architectural Shapes Keystones.

Looking to spruce up the exterior of your home or patio, but don’t quite know what to add?

Perhaps you feel as if your renovations are lacking and require a more stylish element. Keystones can provide this much-needed element for various architectural structures. Consider supplementing your bare arches, dull windows, or empty corridor entrances with your very own custom Keystone.

Decorative Architectural Shapes provides custom solutions to all these problems at an affordable cost. At some point, many homeowners and business owners seek to refresh the architectural integrity of their property. One detail that is overlooked is a keystone.

Companies We Serve

Who Is This Solution For?

Keystones are generally used as an ornament

Positioned at the apex of an arch. Typically, over windows, doors, corridors, and hallways. Before keystones could be fabricated out of foam, they had to be molded either from stone or wood. This was very difficult to do, time-consuming, and was very costly. Thanks to the technological wonder of high-density EPS foam, it is no longer as strenuous and expensive to create the keystone that you want. Decorative Architectural Shapes specializes in crafting custom architectural accents which include keystones.

Our keystones combine the durability of stone with the cost-effectiveness of high-density polystyrene. Take advantage of the opportunity to create your very own keystone design.

Decorative Architectural Shapes products are ideal for new constructions and renovations alike. To quickly receive a quote, please give us a call.

Keystones are generally used as an ornament

Positioned at the apex of an arch. Typically, over windows, doors, corridors, and hallways. Before keystones could be fabricated out of foam, they had to be molded either from stone or wood. This was very difficult to do, time-consuming, and was very costly. Thanks to the technological wonder of high-density EPS foam, it is no longer as strenuous and expensive to create the keystone that you want. Decorative Architectural Shapes specializes in crafting custom architectural accents which include keystones.

Our keystones combine the durability of stone with the cost-effectiveness of high-density polystyrene. Take advantage of the opportunity to create your very own keystone design.

Decorative Architectural Shapes products are ideal for new constructions and renovations alike. To quickly receive a quote, please give us a call.

Custom Keystone Design: Tailored to Your Style and Taste

Our staff would be pleased to assist you in designing a keystone that you feel best suits your décor and taste. We guide you through the size, coating, color and surface finish entirely. Do not hesitate to inquire about creating your own custom design, we welcome all ideas.

If you’re searching for beautiful and stylish architectural keystone which combine durability with a timeless good look, Decorative Architectural Shapes is the right place. Take your time and browse our comprehensive collection of architectural Decorative Architectural Shapes Keystone products alongside with Decorative Architectural Shapes stucco trims, stucco moldings, stucco cornices, decorative moldings, exterior window trims, etc.

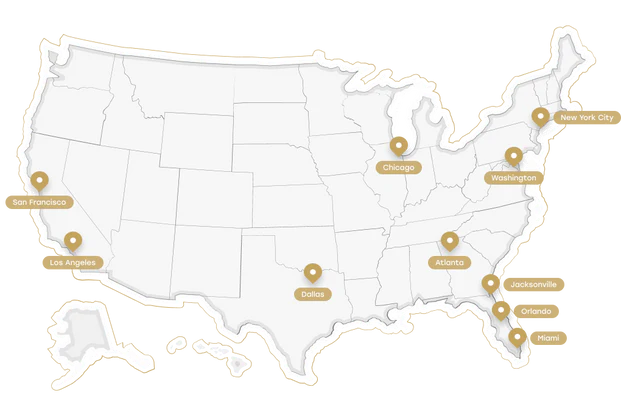

Areas We Service

We proudly serve clients across the United States, including major cities such as

USA: · Jacksonville · Orlando · Miami · Atlanta · Dallas · Los Angeles · New York City · Chicago · Washington · San Francisco ·

Keystones are generally used as an ornament

Decorative Architectural Shapes Keystones can modernize exterior of any house, giving it a fresh look and feel. You can choose a pattern of Decorative Architectural Shapes Keystones that will blend finely with your decorating ideas or one that accents the whole house. Decorative Architectural Shapes has many sizes that can be coped to accommodate our arches, pediments and window heads.

There are four major parameters to consider while choosing the right keystone architectural products: size, shape, quality, and design. One look at our online collection of Decorative Architectural Shapes Keystones will give enough ideas to delight any decorator. With a little patience and the right Decorative Architectural Shapes Keystone the process of exterior decoration can be a very rewarding and enjoyable experience.

Make Sure To Check Keystones And Columns, They Beautifully Add On To The Arches And Create Complete Look.

How to Order From Royal Foam

Step 1. Ready design

If you have a finished project, we adapt it for production and installation, preserving every detail.

Step 2. Define your vision

Capture a clear picture of the client’s ideas before moving to design and rendering.

Step 3. Plan specifications

Outline measurements, production methods, and finalize materials, components, and finishes.

Step 4. Installation

Our team ensures precise setup, perfectly aligning your custom surround with the space.

Step 1

The aim of this step is to capture a precise picture of the client’s vision before proceeding to technical design and visual rendering.

Step 2

During this phase, we define the specifications, production methods, and measurements, while finalizing the look by selecting materials, elements, and finishes.

Step 3

Once fabrication is complete, our installation team will handle every aspect of the setup, ensuring your custom surround is fitted with accuracy and seamlessly integrated into your space.

Testimonials

I highly recommend the services of Royal Foam because they are always consistent with their quality of 3D letterings and other products.

Samuel Ridge

Thank You Royal Foam for providing me with the gorgeously designed monument sign I had ordered for my newly opened company.

Danial Bryan

After installing an arch from Royal Foam not only the look has improved but also my home has become a lot more spacious. I suggest and thank Royal Foam. I will contact again to Royal foam for my new arch work at my home. Designs are very good and finishing is also good.

Amy Corey

I had ordered plastic letters to put up in front of my Company and I’m thanks to the quality, come rain or sun, they shine like new always. Thank you for such good products Royal Foam.

Origin Teak

Frequently Asked Questions

Blog posts

-

Royal Foam US Receives 2023 Best of Jacksonville Award

Read nowPress Release FOR IMMEDIATE RELEASE Royal Foam US Receives 2023 Best of Jacksonville Award Jacksonville Award Program Honors the Achievement JACKSONVILLE April 20, 2023 -- Royal Foam US has been selected for the 2023 Best of Jacksonville Award in the...

-

-

2022 BEST OF JACKSONVILLE AWARD

Read nowAugust 16, 2022 - Royal Foam US has been selected for the 2022 Best of Jacksonville Award in the Architectural Designer category by the Jacksonville Award Program.

Architectural arches

Stand in a busy street for five minutes and see what your eyes do. They drift toward the curve. A storefront capped by a flat arch. A chapel framed by a tall pointed arch — pure gothic architecture, pulling you upward whether you planned to look or not. A stadium roof traced by a single parabolic arch that doubles as the building’s signature.

That’s the quiet power of architectural arches: they solve a structural problem and, at the same time, give a project identity. Straight lintels can hold a wall; arches make a place feel intentional. And with current production methods, the curve is no longer a luxury detail. It’s fast to fabricate, light to handle, predictable to install — in other words, practical.

A quick tour through centuries — curves that built cities

The roman arch (a semicircular arch at heart) was the enabler: aqueducts crossing valleys, amphitheaters holding crowds, bridges that refused to fail. The trick was compression. Stones wanted to fall, but instead locked together. Simple idea, huge consequence.

Medieval builders changed the angle and changed the rules. The pointed arch was the unlock that let gothic architecture chase height and light. Loads went down instead of sideways, so walls could thin, and stained glass could expand. Stand under a nave and you still feel it — the space almost breathes, a reminder of how the pointed arch reshaped.

Elsewhere the language shifted. In Islamic traditions, horseshoe arches and the keyhole arch drew deep shade in hot climates and set a rhythm of light and shadow across courtyards. Renaissance design leaned back into order with the round arch and semicircular arch — calm, measured, reassuring. Then came the engineer’s century: the segmental arch for bridges, the broad tudor arch for collegiate courts, the delicate ogee arch and symbolic trefoil arch for ornament, and later the precise parabolic arch for long-span halls. Different needs, different curves — same idea: make strength look effortless.

The field guide — types of architectural arches (and when they help)

Arches aren’t one thing; they’re a toolkit. Pick the profile to match the task, the budget, the tone.

- Flat arch — Almost no rise. Reads modern, builds quickly, great for repetitive window runs. When facades want rhythm without noise, this is the quiet answer.

- Pointed arch — The icon of gothic architecture. Loads dive to the ground; openings grow tall. Use a pointed arch when the brief says “give this place a moment.”

- Segmental arch — A slice of a circle. Forgiving under load, friendly to brick coursing, common on bridges and arcades. It’s the practical workhorse.

- Tudor arch — Four-centered and broad. Stately without being stiff, a natural fit for campuses, courtyards, and civic buildings.

- Ogee arch — Concave then convex, like motion captured in stone. Entryways love it; light loves it more.

- Trefoil arch — Three lobes, a motif with symbolism. Subtle in small openings, memorable in screens and niches.

- Triangular arch — Straight lines make a point. Cost-smart, striking against glass and steel; it feels contemporary by default.

- Horseshoe arches — Curve beyond the half circle. Deep shade, deep relief; a strong way to break long colonnades.

- Parabolic arch — Math doing poetry. Long spans, clean thrust lines, the spine of stadiums and big transit halls.

- Round arch — The calm half-circle. Classical, predictable, endlessly repeatable when order is the goal.

- Keyhole arch — Narrow base, rounded crown. Gateways and feature doors use it to be remembered.

- Semicircular arch — The Roman staple. Balanced proportions, simple to detail, stubbornly reliable.

You don’t have to choose only one. Mixing a flat arch rhythm with a few pointed arch accents or segmental arch gateways is a straightforward way to give a facade structure and character at once.

Materials and technologies — traditional look, modern logistics

Historically, an arch meant quarried stone, elaborate plaster, or heavy concrete. Gorgeous, yes — but slow, fragile in transit, and expensive to hoist. Today the same profiles are built with a lighter, layered logic:

- Lightweight cores (EPS or comparable foams) hold the exact geometry without punishing the structure beneath.

- Reinforcement layers (often fiber-reinforced) take the knocks: loading bays, scaffolds, the random on-site bump that always happens.

- CNC cutting keeps tolerances tight. A trefoil arch scheduled at 2500 mm arrives at 2500 mm. Not “close.” Exactly as needed.

- Surface finishes adapt to the design intent: smooth and prepainted, mineral textures that read like limestone, or fine grit for subtle shadow.

- Durability isn’t guesswork. Coatings go through UV exposure, moisture cycling, and freeze-thaw tests. It’s lab stuff, true, but it saves money later. The translation: fewer call-backs, schedules that hold, budgets that don’t wander.

From drawing to dock — the modern production loop

Projects move faster when fabrication behaves like a process, not a gamble. A typical loop looks like this:

- Design translation — Rise, span, and spring points pulled from drawings; profiles rationalized for repeatability.

- CNC shaping — Blocks cut to form: flat, pointed arches, segmental arches, tudor, parabolic arch runs, etc.

- Edge reinforcement — High-risk corners and arrises get additional strength for handling.

- Protective coating — Specified by climate and abuse level (coastal air? busy ground floor? plan for it).

- Inspection — Each round arch, ogee arch, or keyhole arch checked for symmetry and size.

- Packing & labeling — Pieces numbered, bundled by elevation, and loaded in install order. Site crews appreciate this more than they’ll admit.

- Unusual requests — a perforated screen with triangular arch cutouts, a long arcade of semicircular arch bays, a single symbolic trefoil arch — still fit. The difference now is predictability: estimates you can defend, lead times you can actually meet.

Installation and upkeep — the part crews care about

Reality on site is rarely the tidy diagram. Walls aren’t perfectly plumb; weather ignores calendars. That’s why the install sequence favors simplicity:

- Tools: adhesives and caulk. No cranes for typical sizes.

- Speed: dozens of profiles set in days, not weeks; wet trades minimized.

- Field trim: small misalignments are corrected on the spot — without starting over.

- Finish: order a primed version and paint immediately or keep the as-supplied texture; both options are normal.

Maintenance? Light. Occasional washing; repaint when color schemes change. Unlike wood, nothing swells or rots. Unlike plaster, nothing hairline-cracks by month three. Over a decade, that difference stops being theoretical and starts showing up in the operating budget.

Cost and value — not just cheaper, smarter

Stone will always impress. Concrete will always last. But both pull schedules sideways and raise line items upstream (reinforcement, lifts, labor). The lighter route changes the math:

- Labor trimmed by ~30–40% — fewer trades, less rework, faster learning curve.

- Transport costs drop — lighter loads, simpler handling, smaller crews.

- No structural upgrades for most conditions — dead load goes down; options go up.

- Storage behaves — profiles stack, wait, and don’t demand space you don’t have.

Picture a mid-rise block with repetitive openings. Swap heavy concrete trims for light profiles: the facade package tightens, a few weeks fall off the program, and contingency stays intact. Market appeal doesn’t suffer; decorative arches actually raise it. That's the value in two ways: cost and demand.

Case study — a housing complex that didn’t try too hard (and that’s the point)

Brief: stand out in a crowded district, stick to a strict budget, don’t slip the schedule. The strategy used the toolkit instead of a single hammer:

- Flat arch runs for window rhythms — clean, disciplined, quick to set.

- Segmental arch gateways at entries — strong, practical, slightly softer than a square opening.

- Select pointed arch moments — measured drama to anchor the composition.

What happened next:

- ~35% lower structural load, which simplified adjacent detailing.

- Install time halved against the original concrete concept.

- Finishing costs reduced ≈25%, with fewer wet trades late in the program.

- Sales velocity improved — renderings had presence, and buyers noticed (comments actually mentioned the arches).

An extended bonus: the team avoided several crane days during facade works. That wasn’t in the first spreadsheet; it mattered in the final one.

Beyond buildings — the arch as a working idea

The arch is more than a shape; it’s a logic. You’ll see it outside architecture:

- Custom insoles for high arches spread pressure across the foot the way a segmental arch spreads load: not in one spot, across the curve.

- Custom balloon arches at events move people, frame thresholds, and signal “this is the entrance.”

- Custom arches in landscape design do two jobs at once: they guide the walk and edit the view.

Different scale, same principle: curves solve problems that straight lines don’t.

Practical specification notes — small choices, big payoffs

- Climate: coastal or high-UV zones deserve tougher coatings. It’s cheaper to spec that upfront than to repaint early.

- Repetition vs. one-offs: repeat counts love CNC. If the drawing repeats, so should the profile file.

- Tolerances: agree on joint widths and reveal lines. A flat arch run will look “off” if the shadow gaps wander.

- Mix profiles: pairing a round arch colonnade with a single keyhole arch entry is a simple way to create hierarchy without cost spikes.

- Access planning: set deliveries in install order. It sounds obvious; it saves hours.

From a semicircular arch marching across an aqueduct to a parabolic arch lifting a roof in one clean line, curves have never been only about beauty. They help spaces work, help people move, help facades speak. Right now — with CNC files, tested coatings, and sane logistics — they also help timelines and budgets behave. That combination is rare.

So if a project needs identity without drama, structure without mass, or simply a better way to frame an opening, the answer is often hiding in plain sight: use the arch. Use the right one — flat arch, segmental arch, round arch, pointed arch, tudor arch, ogee arch, horseshoe arches, keyhole arch, triangular arch, trefoil arch, parabolic arch — and let the curve do what it’s always done: carry the load, carry the story.