Carved Corbels - Custom Design With Detail Precision

Who Is This Solution For

Carved Corbels — Timeless Architectural Detail

Carved corbels bring depth, character, and classical charm to both interior and exterior spaces, seamlessly bridging traditional craftsmanship with modern engineered performance. At Royal Foam, our corbels are precision-crafted from reinforced architectural foam for exceptional stability, durability, and weather resistance. They deliver the rich look of wood carving without the common issues of swelling, cracking, or heavy weight. Perfect for commercial, residential, and branded environments, our corbels arrive fully finished and ready to install. Enhance your project’s aesthetic impact with beautifully detailed corbels designed for real-world performance.

Design and Functionality

Royal Foam decorative corbels are available in a wide variety of styles and designs. There are minimalist models with clean lines and diagonals, as well as more intricate options featuring floral carvings, grape leaves, and other ornamental details. Due to their shape and width, corbels are most often used as decorative elements, adding expressiveness and artistic refinement to the façade.

Architectural Accents for Home Exteriors

The faсade is the face of your home — the first thing people notice and what defines its overall impression. It reflects your taste and the character of the architecture. To highlight the style and individuality of your building, use decorative elements such as brackets, corbels, and other architectural accents.

Royal Foam decorative corbels are an elegant solution that adds expressiveness and sophistication to any façade. They perfectly complement cornices, columns, arches, and other exterior elements, creating a harmonious, refined, and visually appealing architectural appearance.

How We Work

How to Order from Royal Foam

Step 1. Adaptation

If you have a finished project, we adapt it for production and installation, preserving every detail.

Step 2. Define your vision

Capture a clear picture of the client’s ideas before moving to design and rendering.

Step 3. Plan specifications

Outline measurements, production methods, and finalize materials, components, and finishes.

Step 4. Installation

Our team ensures precise setup, perfectly aligning your custom surround with the space.

Step 1. Define your vision

The aim of this step is to capture a precise picture of the client’s vision before proceeding to technical design and visual rendering.

Step 2. Plan specifications

During this phase, we define the specifications, production methods, and measurements, while finalizing the look by selecting materials, elements, and finishes.

Step 3. Installation

Once fabrication is complete, our installation team will handle every aspect of the setup, ensuring your custom surround is fitted with accuracy and seamlessly integrated into your space.

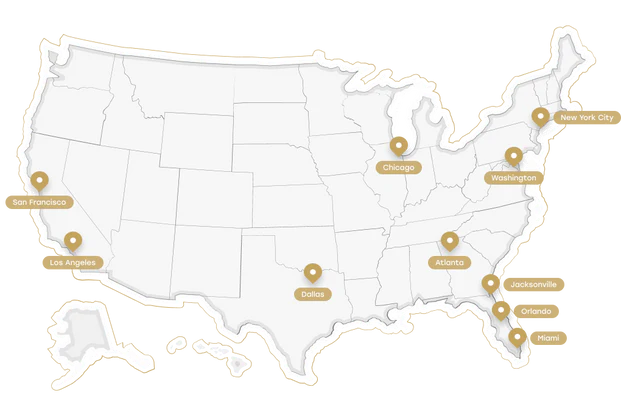

Areas We Serve

We proudly serve clients across the United States, including major cities such as

· Jacksonville · Orlando · Miami · Atlanta · Dallas · Los Angeles · New York City · Chicago · Washington · San Francisco ·

Companies We Serve

Testimonials

I highly recommend the services of Royal Foam because they are always consistent with their quality of 3D letterings and other products.

Samuel Ridge

Thank You Royal Foam for providing me with the gorgeously designed monument sign I had ordered for my newly opened company.

Danial Bryan

After installing an arch from Royal Foam not only the look has improved but also my home has become a lot more spacious. I suggest and thank Royal Foam. I will contact again to Royal foam for my new arch work at my home. Designs are very good and finishing is also good.

Amy Corey

I had ordered plastic letters to put up in front of my Company and I’m thanks to the quality, come rain or sun, they shine like new always. Thank you for such good products Royal Foam.

Origin Teak

Frequently Asked Questions

For example, in one coastal project the homeowners provided us with a sample of their real timber beams. Our task was to create corbels with an aged-oak texture that would seamlessly match those beams. Once installed, the match was so precise that even the installers themselves couldn’t tell where the real wood ended and our corbels began.

Blog posts

Carved corbels

In architecture, there are elements that quietly carry the weight of style, atmosphere, and brand identity. Carved wood corbels belong to this category. They add depth, character, rhythm, even a sense of authenticity that cannot be replicated by minimalist panels or flat facades alone. And when these elements must be installed on real projects — commercial properties, hospitality venues, residential complexes, branded environments — the expectations change dramatically. Precision matters. Durability matters. Compliance matters. Predictable timelines matter.

That is why we design and manufacture carved corbels not as decorative add-ons, but as engineered components that integrate into real architectural systems. Our goal is simple: offer the aesthetic richness of classical craftsmanship with the stability, safety, and accuracy expected from modern American construction. Today, our clients often ask whether it’s possible to achieve the look of traditional wood carved corbels without the swelling, cracking, or unpredictable behavior of natural wood. Or whether hand carved corbels can be used in commercial environments without maintenance headaches. Yes — that’s exactly why we created our current line.

Our products combine digitally controlled shaping, reinforced composite layers, and hand-finished detailing. The result: carved wooden corbels that look like solid timber but exceed natural wood in stability, longevity, and weight efficiency. All made in the USA, fully finished, compliant with IBC requirements and ASTM fire-safety classifications, backed by a 20-year warranty.

What carved corbels are and why they still matter

For centuries, corbels supported beams, rooflines, balconies. Today they are mostly decorative — but no less meaningful. They help anchor style. They soften transitions between materials. They emphasize entrances, create zones inside commercial spaces, introduce hierarchy into façades.

Wooden carved corbels solve several architectural and design tasks at the same time.

It is an important, expressive architectural accent — one that you feel both when approaching the building and when standing inside the space — all without affecting the structural components of the building. At the same time, corbels perform exceptionally well at hiding and masking functional, mechanical, and electrical communication systems.

Third, they bring classical aesthetics even into modern interiors, adding depth, style, scale, and creating a premium architectural appearance. They also enhance the visual value of a space, which is especially relevant for commercial environments such as hotels and retail chains. Corbels help unify decorative and architectural brand elements, forming a cohesive visual language and overall stylistic identity.

A few years ago, we worked on the entrance group of a building where the owner wanted to establish the look and feel of a French chalet. Some architectural elements were already in place, so we needed to work within the existing space. We engineered the corbels considering every nuance of the geometry, scale, and layout. When the corbels were installed, their finish — a warm vintage patina — looked so authentic that the owner was genuinely surprised and said it seemed as if they had been crafted by hand a hundred years ago. That reaction is the clearest confirmation that we achieved exactly what we set out to do.

Materials and engineering approach

Corbels that serve as visual equivalents of real wood are not carved from timber. Instead, we use high-density architectural foam, rated at 18–22 lb per cubic foot, which is reinforced with a multi-layer polymer system that essentially works like a protective “layered shell.” This material behaves predictably in conditions of high humidity, heat, temperature fluctuations, and intense UV exposure. This is especially important for Florida and Georgia — our most active regions — where such stability is absolutely critical.

Below are the stages of production and fabrication of our architectural elements:

Production of architectural elements and quality control during fabrication include the following stages:

- creating a 3D model with an accuracy of up to 1/32 inch

- shaping the architectural form on a CNC machine with a tolerance of 0.3–0.5 mm

- hand finishing of profiles — this is where the “hand carved corbels effect” comes to life

- reinforced coating system for impact, UV, and moisture resistance

We carry out full factory painting for every architectural element, including precise color and shade matching based on the samples you provide. Moreover, we prepare several finish variants so that you can be absolutely certain that the final color perfectly aligns with your project.

Quality control benchmarks

- adhesion testing according to ASTM D3359

- flame-spread performance tests in compliance with ASTM E84, Class A

- UV stability testing up to 800 hours (ASTM G154)

- impact tolerance customized depending on project specification

- structural geometry scanning for dimensional accuracy

All wood carved corbels leave our facility fully finished — no sanding, priming, or additional coating on site. In real projects this often saves two to four days of labor.

Varieties of carved corbels and where they perform best

Different environments demand different properties. Below — a practical overview of how various hand carved wooden corbels and related configurations perform in interiors, façades, commercial zones, and restoration environments.

Interior carved corbels

Used under beams, shelving, bar areas, upper cabinets, reception desks. Interior spaces require lighter designs, gentle radiuses, smooth textures, and consistent color reproduction.

Three parameters matter most:

- installation height (below 8 ft, 8–12 ft, or above 12 ft)

- proximity to human traffic

- desired level of visual emphasis

In Tampa we customized a series of low-depth wood carved corbels (3/8 inch carving depth) to create a heavy visual under-bar effect without actual load. The installation took one evening — no adjustments on site.

Exterior carved corbels

We applied specialized reinforced protective coatings that provide UV resistance and allow the façade to respond correctly to temperature changes. We calculate material expansion coefficients and evaluate wind-load reactions — a critical factor for projects in coastal areas, where enhanced stability of up to 120 mph wind conditions is often required. We also consider water-shedding geometry to ensure long-term performance.

For example, in Jacksonville, when we worked on a coastal-style entrance for a boutique hotel, we engineered reinforced corbels with a hollow interior. The visual mass was preserved 100 percent, yet the facade was not overloaded. All the necessary technical and engineering factors were taken into account to ensure the corbels would perform reliably even in coastal conditions with elevated wind exposure.

Commercial and branding environments

Retail and hospitality spaces often use custom carved corbels to support brand identity. For a multi-location café concept in Atlanta we created a hybrid profile: a classic volute combined with stepped modern geometry. These corbels repeated throughout signage, bar zones, and service counters — becoming a recognizable aesthetic signature across all locations.

Transition and service areas

In many projects, secondary corridors or back-of-house passages create visual “gaps” in stylistic continuity. We frequently design simplified wooden carved corbels to maintain the design language across these zones without unnecessary cost or complexity.

Engineering table: varieties, materials, compliance, applications

| Product type | Core material | Finish/textures | Approx. weight (lb/ft) | Mounting method | Fire classification | Best application zones | Engineering notes |

|---|---|---|---|---|---|---|---|

| Interior carved wooden corbels | HD foam 18–20 lb/ft³ | Reinforced coating, wood texture | 0.8–1.2 | Screws + adhesive | Class A (ASTM E84) | Bars, shelves, cabinetry, reception desks | Reinforced screw zones, minimum depth 2.5", radius-softened edges for safety. |

| Exterior wood carved corbels | Foam 20–22 lb/ft³ | UV-resistant armor coat | 1.0–1.8 | Screws to blocking / metal plates | Class A | Façades, soffits, entry designs | Expansion joints recommended; geometry optimized for water shedding; wind load up to 120 mph. |

| Heavy-look solid wood carved corbels | Foam 22 lb/ft³ with internal reinforcement | Deep wood texture, multi-layer staining | 1.5–2.3 | Hidden brackets | Class A | High-impact visual accents | Hollow inner chamber reduces torsion load; strengthened bracket zones. |

| Premium hand carved corbels | Foam 20 lb/ft³ + hand finishing | Antiqued or patina finishes | 1.0–1.6 | Screws + anchor zones | Class A | Luxury interiors, boutique retail | Tolerance 0.3 mm; consistent shadows through optimized geometry. |

| Custom carved corbels | Foam 18–22 lb/ft³ | Wood, stone, or metal texture | 0.9–1.8 | Mixed hardware systems | Class A | Branding environments, multi-location rollouts | Full shop drawings, 3D models, color samples included. |

| Restoration hand carved wooden corbels | Foam 20–22 lb/ft³ | Aged wood texture | 1.2–1.9 | Mounting to irregular bases | Class A | Historic restorations, period replicas | Engineered tolerance for uneven substrates, custom mounting guides provided. |

Each item is supplied fully assembled and fully painted, requiring zero finishing work on site.

Why choose us: safety, engineering discipline, and 20-year warranty

Working with us means gaining a partner that manages the entire lifecycle of carved wood traditional corbels — from concept sketches to delivery at your location.

Full-cycle integration

- idea and design translation

- engineering models

- shop drawings, sections, and mounting diagrams

- material performance analysis

- factory assembly and finishing

- packaging engineered for transportation

- coordination with freight partners

Our facility produces everything in the USA — allowing strict quality control and stable timelines.

Safety and compliance

Every product meets:

- International Building Code (IBC) criteria

- ASTM E84 Class A fire rating

- relevant local code requirements for commercial interiors and exteriors

- durability standards for humidity, UV exposure, and public-area impact resistance

20-year warranty

We trust our engineering. With proper installation following our specifications, finish and geometry remain stable for decades. That’s why we confidently offer a 20-year warranty.

Real project predictability

In Miami, Orlando, Macon, Gainesville, we repeatedly hear the same feedback: “Everything fit exactly as shown in your shop drawings.” This predictability is one of the strongest economic advantages for contractors, architects, and developers.

If you need hand carved corbels, wooden carved corbels, or advanced custom carved traditional corbels that combine the charm of traditional craftsmanship with the precision of engineered architectural components, we are ready to support your project from the first sketch to the final installation drawings.

Send us your project files — PDF, DWG, 3D models, or even photos — and we will prepare a tailored solution with full documentation and technical clarity.

Request a quote. Ask for samples. Let us help you enhance your next project with engineered traditional corbels made in the USA.