Transform Your Home with Crown Moldings

Increase the value of your home and turn ordinary spaces into extraordinary ones with over 100 designs to match any décor style. Our polystyrene foam Crown Moldings are lightweight, making installation quick and easy. Each piece is factory primed and ready for paint or a custom faux finish. Resistant to moisture, insects, and peeling, they are built to last. Any custom size is available to perfectly fit your space.

High-Quality, Customizable Crown Moldings

Experience sharp design clarity and superior quality with our polystyrene foam Crown Moldings. The textured surface is 100% aggregated acrylic, while the core is molded expanded polystyrene for strength. Pieces can be cut, drilled, glued, or screwed with common tools for effortless customization. Finished with a fast-cure urethane coating, they resist impact and maintain a flawless look. Choose from limitless patterns to complement every interior style.

Testimonials

I highly recommend the services of Royal Foam because they are always consistent with their quality of 3D letterings and other products.

Samuel Ridge

Thank You Royal Foam for providing me with the gorgeously designed monument sign I had ordered for my newly opened company.

Danial Bryan

After installing an arch from Royal Foam not only the look has improved but also my home has become a lot more spacious. I suggest and thank Royal Foam. I will contact again to Royal foam for my new arch work at my home. Designs are very good and finishing is also good.

Amy Corey

I had ordered plastic letters to put up in front of my Company and I’m thanks to the quality, come rain or sun, they shine like new always. Thank you for such good products Royal Foam.

Origin Teak

Frequently Asked Questions

Blog Posts

Custom Foam Crown Molding

Transform Your Interior With Custom Crown Molding

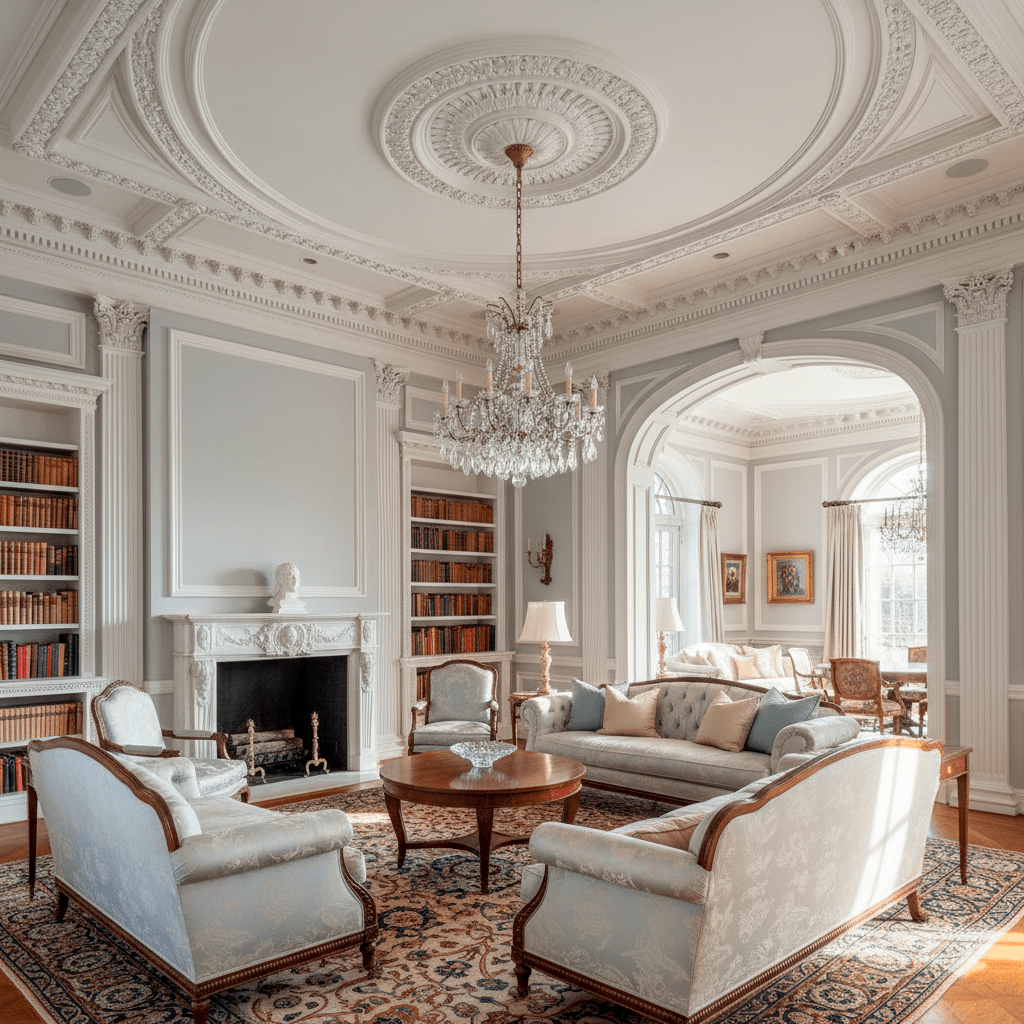

Enhancing a room often begins with details that shape its character, and Custom Crown Molding offers one of the most powerful ways to achieve that transformation. These elegant profiles create smooth transitions where walls meet ceilings, giving your home a refined, finished look. Moreover, modern Crown Molding solutions enhance aesthetics, hide imperfections, and elevate even the simplest architectural layouts.

Homeowners and contractors increasingly choose Foam Crown Molding because it delivers the elegance of traditional wood or plaster without the drawbacks. It is lightweight, stable, moisture-resistant, and remarkably easy to install. Additionally, Custom Crown Molding allows you to match any interior style, from minimalist and contemporary to classic and sophisticated.

Why Molding Matters

Designed initially to conceal uneven joints, Crown Molding now primarily serves a decorative purpose. It visually heightens rooms, adds definition, and enhances architectural flow. Furthermore, the right molding profile strengthens the overall design language, creating harmony across living rooms, hallways, kitchens, and commercial interiors.

Designers often use Custom Crown Molding above windows and doorways as well. This approach unifies the interior and reinforces a consistent style throughout the entire space.

Popular Types of Crown Molding

-

Flat Crown Molding for clean, modern lines

-

Decorative Crown Molding with ornate curves and sculpted reliefs

-

Transitional profiles blending simplicity with subtle detailing

-

Extensive statement moldings for luxury interiors

Each option can be manufactured as Foam Crown Molding, offering durability without excessive weight.

Advantages of Foam Molding

Foam Crown Molding is engineered from high-density expanded polystyrene, providing excellent dimensional stability. Therefore, it resists warping and cracking in any climate. The closed-cell structure blocks moisture, making it ideal for kitchens, bathrooms, and coastal environments. Additionally, protective coatings create a rigid, paintable surface that maintains crisp details.

Installation is straightforward because Foam Crown Molding requires only construction adhesive. Consequently, homeowners and professionals save time, reduce labor costs, and achieve clean, professional results.

In the end, Custom Crown Molding combines beauty, functionality, and long-term performance—bringing elegance to every room with minimal effort.

Crown Moldings

Can a single architectural element combine the properties of decoration, concealment, and insulation? Crown moldings accomplish all these tasks brilliantly. They create elegant transitions between walls and ceilings, drawing admiring glances from every visitor.

Modern homeowners and contractors are increasingly choosing foam crown moldings because they look as elegant as wood or plaster analogues, but last much longer and withstand virtually any conditions.

The extensive Royal Foam collection includes over 100 design options, from elegant, modern crown moldings to sophisticated decorative styles. All are made of high-density expanded polystyrene (EPS) with a factory-applied polyurea hard coat, stucco finish and high quality exterior paint.

What is crown molding, and why does it matter?

Originally, crown moldings were designed to conceal cracks, imperfections, and uneven joints between ceilings and walls. Nowadays, these elements are primarily decorative in nature. They border the rooms, give the impression of visual height, and add a touch of refined architectural character to the space.

Professional designers use crown moldings to achieve a uniform style in both domestic and commercial buildings. The right profile can make low ceilings appear higher, transform plain rooms into luxurious ones, and add value to a property by accentuating architectural details.

Apart from ceiling installation, contractors can install decorative crown moldings above doorways and windows to establish a common theme. This kind of versatility makes moldings essential features in new construction and remodeling.

Types of crown molding: flat vs decorative

Modern crown moldings come in many styles to match different decor. There are two main groups of them:

- Flat crown moldings with straight, clean lines and a minimum of decoration

- Decorative crown moldings - elaborate ones with ornate curves or complex reliefs.

Flat, simple profiles are often used in contemporary interiors, interiors designed in the minimalism spirit. They can also be universal options, suitable for any design, especially when it comes to office buildings or government institutions. Because of its plainness, flat crown moldings provide a crisp transition, which accentuates the solidity of the environment.

Flat, simple profiles work wonderfully in open-plan spaces where the continuity of vision means more than sumptuous details. Their geometry suits modern furniture, clean color schemes, and the sparse space arrangements characteristic of stylish designs.

Modern crown moldings typically project 2-4 inches, which is enough expression to create eloquent spaces without sacrificing the understated elegance that modern design requires.

Decorative moldings, by contrast, feature curves, beads, or scrollwork. Ornate designs like ancient Greek egg-and-dart, acanthus leaves pattern, or layered rosettes create a formal, classic look.

Royal Foam decorative foam crown moldings replicate the intricate details. But unlike wood, our foam pieces resist cracking and warping. High-density and lightweight material maintains its shape in any climate, so even fancy decorative profiles stay flawless over time. Traditional decorative styles typically feature 4-8 inch overhangs with multiple stepped levels, which, when properly lit, create dramatic shadow patterns and add depth to molded spaces.

If desired, you can create a creative combination. Highlight an accent wall with an ornate crown molding, and use plain ones on the other walls. If your inner experimenter hasn't found a suitable design in our standard catalog, you can always order a customized option from our support service by calling (855) EPS-FOAM.

Polystyrene foam crown moldings: lightweight, stable, and durable

Royal Foam manufactures crown moldings using expanded polystyrene (EPS) cores with a highly durable protective coating. This combination offers significant advantages over traditional molding materials.

How EPS crown moldings “behave”

Expanded polystyrene is a true innovation in finishing. It consists of a structure comprising many interconnected closed cells. Due to this, the material possesses such high-quality properties:

- Lightweight construction: EPS foam cores weigh 70–80% less than their solid wood or plaster counterparts, simplifying transportation, handling, and installation.

- Dimensional stability: High-density foam maintains precise dimensions regardless of temperature and humidity changes, eliminating warping, swelling, and splitting.

- Moisture resistance: Foam cells are closed tightly enough that water does not penetrate. Therefore, foam crown moldings can be used in high-moisture locations such as kitchens and bathrooms.

- Impact resistance: Fast-curing urethane coating creates a hard surface that encapsulates the moldings and resists dents, scratches, and impacts both during and after installation, as well as under normal use.

- Pest resistance: Synthetic materials are not a food source for insects, termites, and other wood-destroying pests.

Collectively, these features make foam crown molding a “best kept secret” for decorators and builders. You gain design flexibility and faster installation without a compromise in quality.

Manufacturing quality and finish standards

Each foam molding is treated with multiple protective coatings in the factory's controlled environment. An aromatic urethane base coat infuses the foam surface, followed by an acrylic top coat, primer and paint, to create a prefabricated, ready to install product.

This multi-layer coating system creates crisp design details, with surfaces that can be painted, stained, or faux-finished, just like wood trim.

Crown molding installation: tips and corner solutions

Installing foam crown molding is surprisingly straightforward. In most cases, you simply glue the moldings. For instance, run a steady bead of construction adhesive on the molding's back, then press it tightly to the wall and ceiling. Excess glue wipes off easily.

Decorative crown molding corners: professional solutions

When it comes to corners, manufacturers often simplify the installation process.

- Outside corners: Cut both adjoining pieces with compound miter cuts (typically at 45°), depending on your molding's spring angle. Test fit the pieces before applying adhesive.

- Inside corners: Seasoned installers employ coping cuts rather than simple bevel cuts in these situations. Cut one piece square and trim the neighboring piece to precisely match the molding profile, creating tight joints that won't move with seasonal movement.

- Corner Blocks: Some builders also utilize pre-molded corner blocks, which replace tricky miters with simple butt cuts.

In short, with foam crown molding, you can achieve professional-looking corners using the same saw cuts and coping skills you’d use on wood – without the tedious work of handling heavy pieces.

Tools and materials you’ll need

Successful crown molding installation depends on having the right equipment:

- Cutting tools: Compound miter saw with fine-tooth blade (80-100 teeth) for smooth, splinter-free cuts

- Measuring equipment: Quality tape measure, level, and marking tools for accurate layout

- Fastening supplies: Construction adhesive that doesn’t contain acetone

- Finishing materials: Sealant to complete the installation