Bring Elegance and Warmth to Every Room

Architectural fireplace surrounds turn any hearth into a stunning focal point. Crafted from lightweight, durable materials, they mimic the beauty of natural stone without the heavy lifting. Our designs offer classic and contemporary styles to complement any interior. Easy to install and maintain, they enhance both style and comfort. Transform your fireplace into a centerpiece your home deserves.

Companies We Serve

Who Is This Solution For?

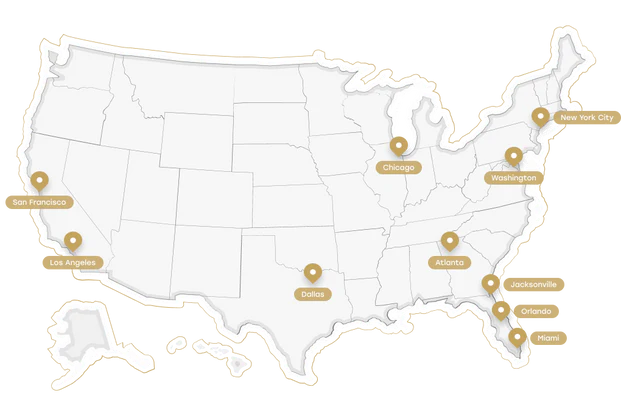

Areas We Service

We proudly serve clients across the United States, including major cities such as

USA: · Jacksonville · Orlando · Miami · Atlanta · Dallas · Los Angeles · New York City · Chicago · Washington · San Francisco ·

How to Order From Royal Foam

Step 1. Ready design

We adapt it for production and installation, preserving every detail.

Step 2. Define your vision

Capture a clear picture of the client’s ideas before moving to design and rendering.

Step 3. Plan specifications

Outline measurements, production methods, and finalize materials, components, and finishes.

Step 4. Installation

Our team ensures precise setup, perfectly aligning your custom surround with the space.

Step 1

The aim of this step is to capture a precise picture of the client’s vision before proceeding to technical design and visual rendering.

Step 2

During this phase, we define the specifications, production methods, and measurements, while finalizing the look by selecting materials, elements, and finishes.

Step 3

Once fabrication is complete, our installation team will handle every aspect of the setup, ensuring your custom surround is fitted with accuracy and seamlessly integrated into your space.

Testimonials

I highly recommend the services of Royal Foam because they are always consistent with their quality of 3D letterings and other products.

Samuel Ridge

Thank You Royal Foam for providing me with the gorgeously designed monument sign I had ordered for my newly opened company.

Danial Bryan

After installing an arch from Royal Foam not only the look has improved but also my home has become a lot more spacious. I suggest and thank Royal Foam. I will contact again to Royal foam for my new arch work at my home. Designs are very good and finishing is also good.

Amy Corey

I had ordered plastic letters to put up in front of my Company and I’m thanks to the quality, come rain or sun, they shine like new always. Thank you for such good products Royal Foam.

Origin Teak

Frequently Asked Questions

Blog posts

-

Royal Foam US Receives 2023 Best of Jacksonville Award

Read nowPress Release FOR IMMEDIATE RELEASE Royal Foam US Receives 2023 Best of Jacksonville Award Jacksonville Award Program Honors the Achievement JACKSONVILLE April 20, 2023 -- Royal Foam US has been selected for the 2023 Best of Jacksonville Award in the...

-

-

2022 BEST OF JACKSONVILLE AWARD

Read nowAugust 16, 2022 - Royal Foam US has been selected for the 2022 Best of Jacksonville Award in the Architectural Designer category by the Jacksonville Award Program.

Fireplace surrounds: lightweight and safe solutions for the coziest interiors

Many homeowners want to complement their interior with a stylish and sophisticated fireplace. And this, of course, adds to the workload of designers and contractors. After all, traditional stone architectural fireplaces are very heavy and prone to cracking over time. In addition, installing a non-standard-shaped fireplace can present additional challenges. What helps smooth out all these rough edges? A modern approach to manufacturing and assembly, as well as a new generation of materials - expanded polystyrene (EPS).

Thematic resources mainly describe the decorative advantages of EPS fireplaces, while their installation requires structural skills and precision. This article shows how Royal Foam creates luxurious-looking fireplace surrounds without the risks posed by conventional fireplace materials.

What fireplace ideas do we offer, and why should you listen to us?

For almost 25 years, Royal Foam has specialized in the production of EPS architectural elements for residential, hotel, and commercial projects across the country. Our foam architectural fireplaces can be integrated into complex interior systems. For example, with these item columns, cornices, or coffered ceiling panels can be ordered together. This approach requires high manufacturing precision and adherence to tolerances when installing multi-component structures. And we fully implement this approach thanks to the qualifications of our specialists and extensive production capabilities. Our company has the largest foam processing plant in Jacksonville.

What fireplace surrounds actually are and what they are made of

Fireplace surround helps to create architectural linkage between the fireplace and the interior. Unlike decorative mantelpieces, architectural fireplaces function as design elements which determine the proportion of the room.

For such systems, we use a “layered construction”:

- high-density core;

- protective hard urethane coating;

- decorative finish imitating stucco, brick, or other coating as desired.

The outcome is a material that resists dimension changes despite temperature and humidity variations. This is fundamentally different from stone (it will crack), wood (it will warp near the heat source), and plaster (stress fractures).

This type of fireplace cladding can be successfully used in the living rooms of residential buildings, the lobbies of luxury hotels, or restaurant halls.

Сharacteristics of EPS foam that you’ll like

The ease of installation and longevity of foam fireplaces can be ensured when the right-density EPS (1.0-3.0 lbs/ft³) material is chosen for a particular fireplace size and performance need.

Lower densities (1.0-1.5 pounds/ft³) are appropriate for large panels where weight reduction is a priority. Medium density (1.5-2.0 lb/ft³) provides the optimal balance for most installations. Finally, higher density (2.0-3.0 lb/ft³) is used for deep overhangs or increased impact resistance.

The protective coating system creates a rigid shell that not only makes the surface fire-resistant but also creates a barrier against moisture and provides temperature stability. Thus, the EPS items retain their structure in a temperature range from -40 °F to 140 °F, which eliminates the appearance of fine cracks that appear on stone after 2-3 heating seasons. The material structure also ensures that butt-jointed parts will not change shape or warp, forming gaps.

The wonders of precision: what CNC cutting gives

In manufacturing components for fireplace surrounds through CNC, we avoid the inaccuracies that are typical of manual cutting. CAD modeling establishes precise geometric parameters and then converts them into tool paths that control operations with 0.5 mm tolerance.

This precision is essential when multiple pieces need to be aligned at once: the frames stand upright, the mantel projections must be of equal depth, and the corbels require perfect symmetry.

For example, a customer wants a classic antique fireplace, custom-made, decorated with egg-and-dart molding, acanthus leaves, and Greek patterns. CNC ensures that all elements will match exactly.

Contemporary custom fireplaces from EPS have asymmetrical geometry, impossible with traditional manufacturing. Floating mantels with concealed fastenings, relief panels with variable depths, organic shapes - all of this is transferred directly from CAD to the finished components.

Weight, ideal for mounting

One of the notable advantages of expanded polystyrene fireplaces is their light weight. The comparison of actual figures will amaze you. For example, 48-inch stone surrounds weigh 400-600 pounds. Such parts require structural assessment and reinforcement (otherwise, the wall of the house simply will not support the weight of the fireplace).

Equivalent EPS foam surrounds weigh just 40-60 pounds. This type of structure can be installed by a single installer using standard adhesive. What's more, the process takes only a few hours. The lightweight means that the adhesive provides sufficient holding power through continuous adhesion across the entire back surface. This prevents stress concentrations that could lead to cracking in the case of stone. With EPS, the installation allows for minor wall irregularities without requiring a perfect base.

Types of fireplace foam surrounds we produce

A cookie-cutter fireplace “like your neighbor's” is the last thing you want to see when designing a sophisticated interior in a classic or contemporary style. Working with Royal Foam guarantees absolute originality. We specialize in customized design and can reproduce fireplace surfacing based on any of your references: from 3D projects to old black-and-white photos.

Below are the four main categories under which surrounds may be procured:

- Classic fireplace cladding that follows traditional patterns: pilasters on either side of the firebox, a frieze, and a protruding mantelpiece.

- Contemporary minimalist surrounds feature clean geometric elements.

- Custom-made fireplaces include relief elements and ornaments.

- Integrated wall systems.

EPS comparison with typical fireplace materials

EPS foam fireplaces offer both technical and economic advantages over traditional alternative materials.

| Parameter | Stone | Wood | Plaster | Foam Surrounds |

|---|---|---|---|---|

| Weight | 400-600 lbs | 80-150 lbs | 100-200 lbs | 40-60 lbs |

| Crack susceptibility | High | Medium | High | Minimal |

| Geometric complexity | Limited | Medium | High (fragile) | Very high |

| Installation duration | 2-3 days | 1-2 days | 1-2 days | 4-8 hours |

| Total cost of ownership | Highest | Medium | Medium | Optimized |

The difference in characteristics is most noticeable in large-scale installations. The hotel lobby fireplace spanning 10-12 feet requires cranes for stone, while foam components are positioned manually. A restaurant with multiple fireplaces in the dining room avoids structural loads that stone imposes, which is critical for second-story installations.

Fireplace design ideas that really worked out: real-life cases

But let's consider the advantages of EPS architectural fireplaces using real projects from the Royal Foam portfolio as examples.

A very large family room in a house in Houston necessitated fireplace surrounds that were 9 feet wide and had a mantel overhang of 8 inches with accompanying side panels that went up the wall 6 feet. The project required travertine cladding with handcrafted decorative brackets holding up the mantel. We manufactured the mantelpiece in three main sections with separate brackets, weighing a total of 75 pounds.It took one day for the two-man crew to install the surround, achieving the aesthetics of heavy stone without actually altering the structure. The project was completed in 2019; and after four heating seasons, there are no cracks from stress or joint separation on the mantel.

For a mountain residence in Vail, the owner ordered custom outdoor fireplaces for covered patios at an elevation of 8,200 feet. In such conditions, the fireplaces would be exposed to temperatures ranging from -20 °F in winter to 90 °F+ in summer. The design called for rough-hewn granite of massive proportions, 60 inches wide and 12 inches thick. A UV-resistant coating prevents deterioration from high-altitude sun exposure. The closed-cell structure of the EPS core eliminates the freezing and thawing problems that cause natural stone to crack in mountain climates. The result is four years of service in Colorado's weather cycles. No dimensional changes, surface degradation, or structural problems have been reported.

You can find more options for EPS fireplace designs in our Cases section [Link to the Cases section].

Profitable calculations: determining TCO

Budgeting for projects is usually centered on material budgets. But labor and structural changes often account for a large portion of the expense when installing traditional fireplaces. Calculating the total cost of ownership (TCO) for the entire project lifetime clarifies the economic advantage of foam.

Stone requires 16-24 hours of labor; foam is installed in 4-8 hours. Taking into account a skilled labor cost of $75-100 per hour, this results translate to savings of $1,200-2,000 per installation. Structural preparation costs are also eliminated: no engineering fees, permits, demolition, or reinforcement materials are required.

Thus, durability removes repairs of damaged stone, warped wood, and plaster. Foam shows minimal wear after 10-15 years, as the material doesn’t react to environmental changes that destroy traditional materials. The maximum service life can reach up to even 100 years.

The flexibility in design allows you to design your own geometric patterns without any extra cost. Even adding some carved details or asymmetric patterns will not exhibit an exponential cost escalation associated with stonework.

Let’s calculate the TCO over 20 years. The material cost at the beginning is 30-40% of the total amount. The remaining costs go for installation, construction work, and maintenance. The expanded polystyrene material optimizes all three aspects and offers the same visual effect.

Installation and technical guidelines

Prepare the base: ensure that the walls are clean, dry, and sufficiently flat. Construction adhesive helps to fix the parts of the mantle initially, and then screws are provided.

According to thermal clearance standards, combustible materials must be at least 6 inches from the sides and 12 inches above the openings of the firebox. Royal Foam manufactures fireplaces to include thermal clearance in the design.

These are some common mistakes made by contractors that can affect the fireplace cladding installations:

- Over-tightening fasteners compresses the foam core;

- Excess adhesive causes it to squeeze-out;

- Not checking plumb/level allows errors to compound;

- Leakage at joints between the components.

Also note that Royal Foam's hard coat offers thermal protection, but surfaces must not come into contact with anything above 140 °F. For wood-burning fireplaces, this typically means maintaining code-required clearances and handling thermal loads adequately. Gas and electric units generate heat in a more controlled way. Verify with the firebox manufacturer that the surround positioning falls within their approved installation range.

Assurance of quality, safety, and guarantee

Royal Foam architectural fireplaces meet interior design standards for homes and business spaces. However, their installation is done with consideration to local codes and firebox specifications.

The closed-cell polystyrene foam absorbs virtually no water, thus being useful in custom outdoor fireplaces for covered patios. The resistance to sun exposure comes from using protected coatings.

We offer a 10-year warranty on all EPS products. The warranty covers dimensional stability, coating adhesion, and structural integrity. We carefully preserve technical specifications and visual references: this allows us to accurately reproduce the necessary parts of the product several years after installation.

EPS foam custom fireplaces are just what you need if your goal is to increase the value of your property or add character to a room. We at Royal Foam deal with each of our projects in a very planned manner so that our products are aesthetically appealing and precisely engineered as well. Our designs warm the soul and are easy on the wallet.

Request detailed technical specifications and quotes by sending a request with just one click [Link to the contact page]. You can also discuss the design features of your future fireplace during a telephone consultation with our specialist.