Transform ordinary columns into stunning architectural statements with our faux stone column wraps

Crafted from lightweight, durable foam, they mimic real stone without the hassle of heavy masonry. Installation is quick and clean, making it perfect for both interiors and exteriors. These wraps add instant elegance and character to homes, offices, and commercial spaces alike. Choose the look of luxury without the weight, cost, or long installation time.

Faux stone column wraps: classic look, modern ease

We’ve lost count of how many times a builder told us: “The buyer wants stone, but the budget just won’t allow it.”

Here’s the thing — when you switch to exterior faux stone post covers, three problems disappear immediately:

- Budget overspend.

- Extended timelines.

- Unpredictable results.

That last one is key. With natural stone, you never really know what you’re going to get until the pallets arrive. Too light, too dark, mismatched… and now you’re wasting labor hours trying to sort it. Faux stone wraps? Uniform. Consistent. Reliable.

How to Order from Royal Foam

Step 1. Adaptation

If you have a finished project, we adapt it for production and installation, preserving every detail.

Step 2. Define your vision

Capture a clear picture of the client’s ideas before moving to design and rendering.

Step 3. Plan specifications

Outline measurements, production methods, and finalize materials, components, and finishes.

Step 4. Installation

Our team ensures precise setup, perfectly aligning your custom surround with the space.

Step 1. Define your vision

The aim of this step is to capture a precise picture of the client’s vision before proceeding to technical design and visual rendering.

Step 2. Plan specifications

During this phase, we define the specifications, production methods, and measurements, while finalizing the look by selecting materials, elements, and finishes.

Step 3. Installation

Once fabrication is complete, our installation team will handle every aspect of the setup, ensuring your custom surround is fitted with accuracy and seamlessly integrated into your space.

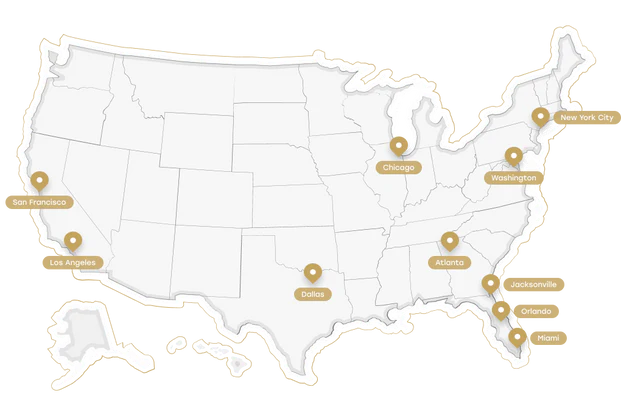

Areas We Serve

We proudly serve clients across the United States,

including major cities such as

· Jacksonville · Orlando · Miami · Atlanta · Dallas · Los Angeles · New York City · Chicago · Washington · San Francisco ·

Companies We Serve

Testimonials

I highly recommend the services of Royal Foam because they are always consistent with their quality of 3D letterings and other products.

Samuel Ridge

Thank You Royal Foam for providing me with the gorgeously designed monument sign I had ordered for my newly opened company.

Danial Bryan

After installing an arch from Royal Foam not only the look has improved but also my home has become a lot more spacious. I suggest and thank Royal Foam. I will contact again to Royal foam for my new arch work at my home. Designs are very good and finishing is also good.

Amy Corey

I had ordered plastic letters to put up in front of my Company and I’m thanks to the quality, come rain or sun, they shine like new always. Thank you for such good products Royal Foam.

Origin Teak

Frequently Asked Questions

Blog Posts

Faux Stone Column Wraps

Faux Stone Column Wraps

Columns have always been a defining feature in American architecture. They’re not just structural supports — they frame the look of a house, a porch, or even a commercial entryway. The truth is, people notice them first.

And yet, the struggle has always been the same: how to get the stone look without blowing the budget or dragging out the schedule. That’s where faux stone veneer column wraps started winning contracts. They give developers, contractors, and property managers what they actually need — real curb appeal at a fraction of the time and cost.

Why Builders Keep Choosing Faux Stone Column Wraps (Even When Clients Ask for “Real Stone”)

We’ve lost count of how many times a builder told us: “The buyer wants stone, but the budget just won’t allow it.”

Here’s the thing — when you switch to exterior faux stone post covers, three problems disappear immediately:

- Budget overspend.

- Extended timelines.

- Unpredictable results.

That last one is key. With natural stone, you never really know what you’re going to get until the pallets arrive. Too light, too dark, mismatched… and now you’re wasting labor hours trying to sort it. Faux stone wraps? Uniform. Consistent. Reliable.

One project manager in Texas told us he bid lower than his competition by switching to wraps. Not only did he win the contract, but the developer asked him to repeat the same system across multiple sites.

Stone veneer column wraps 12x12 vs. 6x6 — Not Just Sizes, But Different Stories on the Jobsite

In our experience, size isn’t just about fit. It’s about the story a building tells.

Faux stone post covers 12x12 — bold, heavy-looking, almost like they’ve been there for a century. Perfect for hotels, restaurants, or homes with big facades.

6x6 wraps — clean, modest, and flexible. Great for porches in residential neighborhoods where proportions matter.

We had a client in the Midwest who tried 6x6s on wide ranch-style homes. The result looked too thin. When he upgraded to 12x12s, suddenly the homes felt balanced. The buyers noticed.

So when people ask us “which size is better?” — we say: neither. It depends on scale, proportion, and sometimes just the personality of the property.

Weather and Wear: How Exterior Faux Stone Column Wraps Handle the Elements Contractors Fear Most

Every contractor has the same nightmare: a product that looks great in June and fails by January. Columns take the brunt of the weather.

That’s why these wraps were designed with climate in mind. We’ve seen them hold up in Minnesota after years of freeze-thaw. We’ve seen them sit in the Arizona sun and keep their color. Down in Florida, they don’t mold. Near the coast? Salt air doesn’t chew them up.

One of our favorite follow-up calls came from a New England homeowner. Three winters after install, she said: “They still look brand new — my neighbors think we just had them done.” For us, that’s proof you can trust.

Foam-Based Faux Stone Column Wraps vs. Natural Stone — The List of Wins That Keep Budgets Alive

When you line up foam-based wraps against natural stone, the differences are too obvious to ignore:

- Weight — no cranes, no structural reinforcement. One guy can carry a panel.

- Cost — we’re talking savings on freight, labor, and waste. Stone bleeds a budget dry; foam doesn’t.

- Time — real stone eats up days. Wraps take hours. And yes, we’ve seen porches finished in a single afternoon.

- Durability — stone chips, stains, and cracks. High density foam doesn’t absorb water, doesn’t fade, and doesn’t need sealing.

- Safety — crews love not wrestling with heavy blocks. Fewer accidents, less liability.

If you’re a developer looking at ROI, that list speaks for itself. And let’s not forget logistics. We’ve had projects where simply cutting freight costs made the wraps pay for themselves before the first install even began. Try getting that with stone.

Design Styles with Faux Stone Porch Column Wraps — From Farmhouse Charm to Hotel-Grade Impact

Design is where faux stone becomes fun. You’re not locked into one look.

We’ve used rustic textures on farmhouses that made porches look warm and inviting. We’ve delivered sharp, stacked stone finishes for modern commercial buildings that scream contemporary. On a recent subdivision project, the builder mixed styles across models — buyers thought each home was “custom,” but behind the scenes, installation was fast and repeatable.

That’s the balance every developer dreams of: variety for buyers, consistency for crews.

Case Studies: Faux Stone Veneer Column Wraps That Sold Homes Faster and Kept Restaurants Open

Let us tell you a few stories.

A builder in the Midwest swapped out plain wood posts for 6x6 faux stone wraps. His words: “It was like flipping a switch. Buyers walked in and instantly saw value.” The homes sold faster, and he’s still ordering more.

A restaurant owner wanted a bold new look but couldn’t afford downtime. The entry posts were wrapped over a weekend. Monday morning, customers walked in saying: “Love your new stone columns!” Nobody guessed they weren’t real.

And then there was a hotel chain. Deadline pressure was brutal. They needed a grand entrance but had no time for masonry. We supplied 12x12 wraps. The project finished on schedule, under budget, and the property looked like it had been hand-crafted from stone. One staff member told us: “Guests keep asking who our stone mason is.” That’s what we call invisible success — the work stands out, but the effort doesn’t.

Additional Case 1 — Residential Developer

We worked with a developer building 50 single-family homes. By choosing faux stone wraps instead of natural stone, they saved nearly three weeks on the overall timeline. That meant the homes hit the market before competitors, and sales were faster. Buyers didn’t care that it wasn’t “real stone” — they just saw curb appeal.

Additional Case 2 — Commercial Plaza

A retail complex wanted a unified look across multiple storefronts. Installing masonry on every column would have been financially impossible. Foam-based wraps gave the same look, and the whole plaza was completed ahead of schedule. Tenants were able to open earlier — and that meant rent revenue sooner.

Eco-Friendly Faux Stone Post Covers — Why Developers Use “Green” as a Selling Point

More and more, cities and buyers are asking for sustainability. Natural stone comes with quarrying, heavy transport, and high emissions. Faux stone wraps sidestep all of that.

They’re lighter to ship, which saves fuel. They don’t need replacement for decades, which cuts down on waste. And yes, in some applications they even help with insulation.

We’ve had developers specifically choose wraps because they could highlight eco-friendly materials in their sales brochures. For them, it wasn’t just about saving money — it was about marketing.

Custom Faux Stone Veneer Column Wraps: When “Standard Sizes” Just Don’t Cut It

Standard 6x6 or 12x12 works 80% of the time. But sometimes, it doesn’t.

That’s why customization matters. We’ve built oversized wraps for commercial plazas where nothing “standard” would fit. We’ve also color-matched wraps to blend perfectly with brickwork, so entire columns looked like they’d been there forever.

When every detail matches the architecture, buyers don’t see “a product.” They see a design that feels complete. That’s where we come in.

The Future of Exterior Faux Stone Veneer Column Wraps — Where Innovation Meets Deadlines

Lightweight architectural products aren’t going anywhere. Every year, textures get sharper, finishes more realistic, and installs even faster.

And deadlines? They’re not getting kinder. Which is why wraps are only going to be more important. Developers want beautiful exteriors, but they can’t wait. Foam-based faux stone is the bridge between design dreams and construction reality.

Why Royal Foam Is the Partner Contractors Actually Trust With Faux Stone Post Covers

A lot of suppliers sell wraps. But not many actually understand contractors.

We’ve been on sites where deadlines are brutal, where budgets are tight, and where mistakes cost thousands. That’s why we don’t just ship boxes. We work with you on sizing, textures, and delivery schedules. We know what it means when you say “I can’t afford callbacks.”

What we offer:

- Tailored solutions (sizes, textures, and colors).

- Reliability (products that don’t fail after the first winter).

- Experience (from subdivisions to national chains).

- Consistency (columns that look uniform across dozens of builds).

It’s not about selling you panels. It’s about helping you look good in front of your clients.

And here’s another point contractors often mention: trust. When we say delivery will be on-site Tuesday morning, it’s on-site Tuesday morning. That reliability matters when crews are waiting and deadlines are tight. With stone, too often shipments are delayed or mismatched. With us, it’s predictable.

Logistics and ROI — The Numbers Behind Faux Stone Veneer Column Wraps

Here’s something clients don’t always think about: freight. Shipping stone is brutal — heavy loads, high costs, reinforced pallets. Foam-based wraps are lighter, stack neatly, and ship for far less.

And when you add in labor savings, faster installs, and fewer errors, the ROI is obvious. One developer told us: “They basically paid for themselves in the first project.”

Think long-term too. It’s not just the upfront savings. Over decades, no sealing, no repairs, no replacements — that adds up to thousands of dollars saved on every property. For property managers, that’s not a perk, that’s a game-changer.

Request a fast quote!

Contacts

Faux stone column wraps

Faux Stone Column Wraps in contemporary architectural design serve several important functions, far beyond simple decoration. They reduce the structural load, ensure precise geometry, speed up installation, and visually match the intended design with remarkable accuracy. What may seem like an ordinary decorative element actually deserves serious attention and has become a popular choice among architects, designers, and contractors. The combination of practicality, durability, stability, and aesthetic value makes faux stone column sleeves an ideal architectural component for modern projects. That’s why faux stone column wraps 12x12, faux affinity stone column wraps 6x6, faux stone porch column wraps, and high-performance exterior faux stone column sleeves have become one of the most versatile and reliable categories across residential, commercial, and hospitality segments.

We manufacture every component in the United States, ensuring control over everything—foam density, machining precision, texturing, coatings, and packaging. That engineering consistency is what turns installation into a straightforward mechanical task rather than a risky on-site improvisation.

What faux stone column wraps are and why professionals rely on them

Faux stone column wraps are architectural shells that recreate the appearance of natural stone while remaining lightweight and structurally non-invasive. They can encase existing columns, correct visual imperfections, or serve purely as a design element.

Their primary functions include:

- defining and emphasizing entrance zones;

- strengthening façade composition;

- masking aged or uneven structural columns;

- increasing resistance to moisture and UV exposure;

- modernizing a building without structural reconstruction.

The average weight of a 96-inch segment is 8–14 lbs, which is 6–9 times lighter than natural stone equivalents weighing up to 120 lbs per piece.

Materials, engineering parameters, and manufacturing technology

We use high-density architectural foam ranging from 18 to 30 lb/ft³, depending on project requirements. This density range provides the necessary balance between impact resistance and ultra-low weight.

Key engineering parameters:

- water absorption < 1.5% by mass;

- linear thermal expansion < 0.03% between –20°F and +160°F;

- UV resistance > 3000 hours under Xenon Arc testing;

- dimensional deviation < ±1 mm;

- tensile strength approx. 38–45 psi.

Our manufacturing cycle includes three quality-critical phases:

- primary machining and shaping;

- surface texturing and detailing;

- two- or three-layer acrylic-polymer finishing with controlled curing.

All products are shipped fully painted—no finishing is required on site.

Logistics, packaging, and delivery timelines

We partner with freight companies experienced in transporting oversized, lightweight architectural elements. Every product is secured with multi-layer protective packaging and reinforced corner protection.

Typical production time: 5–12 business days.

Deviation from confirmed timelines in 2023–2024: less than 2.7%.

In our practice, spanning nearly a quarter of a century in this field, we have handled the transportation of a wide range of architectural elements — from extremely long columns to large-scale custom structures. Whenever possible, we partially pre-assemble oversized components at our production facility to make the installation process even faster and easier on site.

Because of this, transportation details must always be clarified individually: in each case, we determine whether oversized or non-standard cargo can be shipped as a whole or requires sectional delivery.

If your site is not yet ready to receive the architectural elements we’ve produced, we offer free storage at our facility. We can also arrange phased transportation and staged deliveries to simplify and streamline the installation process at your location.

Cost and measurable project-level savings

Pricing depends on size, height, finish, and volume. Yet the true value of faux affinity stone column wraps becomes obvious when evaluating total project cost. In multi-column installations, TCO (total cost of ownership) decreases by 30–45% due to:

- no need for heavy machinery;

- 2–3× lower installation labor;

- minimized on-site errors;

- zero maintenance requirements;

- no additional load on structural components.

Professional engineering comparison table

| Engineering Criterion | Faux Stone Column Wraps | Natural Stone | Fiber-Cement Systems |

|---|---|---|---|

| Density (lbs/ft³) | 18–30 | 145–160 | 75–95 |

| Dimensional tolerance | ±1 mm | ±4–6 mm | ±3 mm |

| Thermal expansion coefficient | 0.03% | 0.01% | 0.05% |

| Compatibility with existing structures | fully compatible | limited | limited |

| Labor hours per column | 0.8–1.2 | 6–9 | 3–4 |

| Structural load impact | minimal | high | medium |

| Impact behavior | absorbs energy | strong but brittle | moderate |

| Custom textures | unlimited | limited | limited |

| Moisture reaction | <1.5% | 0% | 5–8% |

| 5-year TCO | low | high | medium |

Varieties and application scenarios

In private residential projects, faux stone porch column wraps are most often used for entryway enhancements. They create a sense of monumentality, add character and style to the structure, and make the home appear visually more refined and high-end. One of our recent coastal projects in Sarasota is a good example. We created not just attractive architectural column forms, but replicated a unique coral-stone texture that matched the house’s design with exceptional accuracy. And importantly, neither the load-bearing structure nor the foundation was affected in any way — everything was installed quickly and seamlessly.

Commercial architecture and commercial real estate.

Hotels, retail spaces, boutique environments, hospitality venues, and event spaces frequently rely on exterior faux affinity stone column wraps because they are durable, easy to maintain, and perfectly meet the visual and stylistic requirements of modern commercial properties. We once completed a large custom project for an event venue, where we produced 18 identical columns for the atrium. The most significant part was the installation efficiency — the wrap system reduced labor time by 57%, which made a substantial impact on the overall project schedule and budget.

Restoration and modernization.

Wrap systems are excellent for renovating older buildings, and we work with such projects quite often. Many historic structures originally used gypsum-based decorative elements, and today those components no longer meet durability or aesthetic standards. Faux affinity stone column wraps solve these issues: they mask cosmetic flaws, conceal structural irregularities, and form clean, symmetrical, geometrically accurate profiles without any demolition.

For instance, in a private home renovation project in Tampa, we were tasked with recreating a century-old chiseled stone texture. We reproduced it with remarkable precision. The homeowner kept running his hand over the surface of the new architectural elements, amazed at how authentic it felt.

Installation and maintenance

Installation is mechanical and predictable:

- wrap sections are placed around the column,

- secured with appropriate fasteners,

- seams are concealed with pre-finished trim pieces,

- alignment is checked.

Our step-by-step guide how to install faux stone column sleeves comes with every order.

Maintenance is minimal—routine rinsing with water is enough.

Why working with Royal Foam is genuinely advantageous

Our clients often tell us that we are the first manufacturer they have worked with who truly created a feeling of technical partnership — full communication, trust, and the ability to openly discuss any process, stage, or expected result. We do not behave like a typical product supplier. And this is exactly the outcome we have always aimed for, and continue to aim for today.

Our mission is not to simply deliver standard decorative elements that happen to be in stock. Our mission is to meet your needs as effectively as possible, taking into account every nuance of your project. This is why we produce custom, unique architectural components designed to reflect your idea, your concept, your design vision, while also carrying functional and practical value — not just roughly matching the required size and color.

To achieve this, we do everything that is technically possible.

- We match textures, finishes, and shades individually.

- We compare samples and provide multiple finishing options when needed.

- We apply the same level of precision to geometry and dimensions.

It is critically important for us to deliver architectural elements in a form that allows for an easy, trouble-free installation on site. Whenever feasible, we pre-assemble parts directly at our production facility to simplify the process for your installation team.

When a designer sends us a sample of a painted façade, tile, or any other architectural element, we carefully match the shade so that it fits seamlessly into the overall visual composition — both in natural daylight and artificial lighting.

When engineers send us documentation with dimensional tolerances, we follow them precisely — our deviation does not exceed 1 mm.

When developers require strict schedule stability, we confirm the timelines and consistently adhere to them.

This level of predictability comes from having our own U.S.-based production, strict quality control, personal project managers, rapid estimating, engineering flexibility, eco-friendly materials, storage capabilities, and of course, our 20-year warranty, which we back with full confidence.

We don’t just manufacture a product.

We create a solution.

Conclusion

Faux Stone Column Wraps represent a new generation of architectural forms. They are lightweight, dimensionally precise, structurally strong, visually flawless, and economically efficient. Faux stone column sleeves solve many challenges within a project: they enhance the visual impact, accelerate installation, and give designers the freedom to implement their ideas without the limitations of traditional materials.

If you’re looking for a solution that is not only visually compelling but also practical, cost-efficient, and designed for long-term durability, then faux stone column sleeves are an excellent choice. We provide a 20-year warranty, confidently standing behind the quality of our products and knowing they will perform reliably on your project.

You can send us your drawings or concepts right now, request a quote, and we will prepare a proposal tailored specifically to your project.