Faux Wood Beams Made Of PU Foam - Look Of Natural Wood Effortlessly

Who Is This Solution For

Royal Foam manufacturing process and materials

Faux Wood Beams by Royal Foam US imitate solid wood in geometry and texture, but are not load-bearing beams and do not contribute to the structural integrity of the ceiling.

We manufacture Faux Wood Beams exclusively from

high-density (<15 lb/ft³) polyurethane foam.

Our specialists use PU Foam as a shaping material. It allows us to create beams with thin walls, clear geometry, and a deep wood grain. The wall thickness allows us to maintain visual solidity while minimizing weight.

Hard Coat Polyurea protective coating is optional for products made of PU Foam. We use it for engineering purposes, such as outdoor applications, high-risk mechanical areas, and public spaces.

Hard Coat Polyurea provides increased impact resistance and moisture resistance. It stabilizes surfaces and extends the product's lifespan.

Custom Faux Wood Beams

Available forms:

- U-shaped beams;

- L-shaped beams

- Straight sheets

- Box-shaped beams;

We specify the texture and color during production as part of the approved visual system.

Available styles and textures:

Economics and Regulatory Framework

The total cost of ownership is the cost of a product over its entire lifespan. You need to factor in not only the cost of the material itself but also its installation, as well as all future maintenance, upkeep, and repair costs. The price of the material can be comparable to or slightly higher than that of some alternatives. But this is the price for a finished, perfect product that requires no additional processing. The lack of structural load means the beams don't support anything - they can be hung anywhere. This immediately reduces the design effort. The beams are lightweight, cut with a regular saw. The work takes hours, not days. This significantly reduces labor costs.

The savings increase over the years. The beams are unaffected by humidity and temperature fluctuations, unlike natural wood. They won't warp or crack. This keeps operating costs minimal. In the long run, you benefit from very low-cost installation and virtually zero maintenance.

Installation Logic

You can securely attach the structure to the walls or ceiling. For this, use either wooden blocks or pre-cut metal strips. Attach with a special, powerful adhesive that holds tightly, or with hidden locks and fasteners that are invisible to the naked eye. You won't need to assemble the structure with bulky cranes or machinery; a small team can handle it.

You won't need to reinforce floors or ceilings specifically, since the system itself is lightweight. There's no need to install heavy and expensive load-bearing metal beams. Everything is clean, quick, and mess-free.

We strictly adhere to ASTM standards in our work.

Our products meet the most stringent standards. Be assured of their quality and safety.

Faux Wood Beams are an engineered alternative to solid wood beams.

They allow you to achieve the visual authenticity of wood without the weight, deformation, or operational risks.

The system provides stable geometry, precise texture, and a low total cost of ownership.

How We Work

How to Order From Royal Foam

Step 1. Ready design

We adapt it for production and installation, preserving every detail.

Step 2. Define your vision

Capture a clear picture of the client’s ideas before moving to design and rendering.

Step 3. Plan specifications

Outline measurements, production methods, and finalize materials, components, and finishes.

Step 4. Installation

Our team ensures precise setup, perfectly aligning your custom surround with the space.

Step 1

The aim of this step is to capture a precise picture of the client’s vision before proceeding to technical design and visual rendering.

Step 2

During this phase, we define the specifications, production methods, and measurements, while finalizing the look by selecting materials, elements, and finishes.

Step 3

Once fabrication is complete, our installation team will handle every aspect of the setup, ensuring your custom surround is fitted with accuracy and seamlessly integrated into your space.

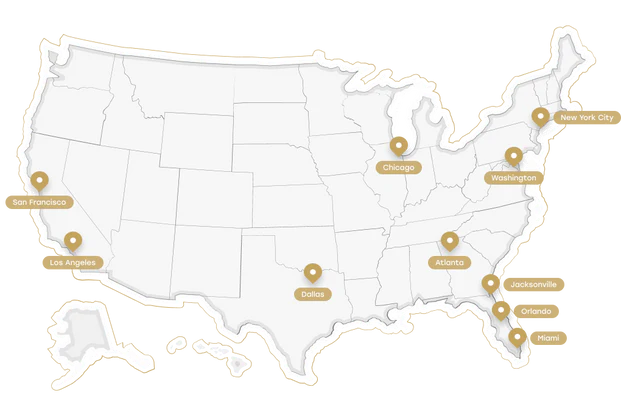

Areas We Serve

We proudly serve clients across the United States, including major cities such as

· Jacksonville · Orlando · Miami · Atlanta · Dallas · Los Angeles · New York City · Chicago · Washington · San Francisco ·

Companies We Serve

Testimonials

Always wanted that rustic cabin feel in our living room, but real wood beams are crazy heavy and expensive. Royal Foam’s faux wood beams in EPS were the answer. Free consult helped me figure out the sizing. They look 100% authentic, cost a fraction of real timber, and I installed them myself with zero help. Game changer.

Greg Morrison

We have a low ceiling, and real beams would’ve crushed the room. The grain detail is insane - looks hand-hewn. They re lightweight, so no structural reinforcement is needed. Our contractor was shocked. Highly recommend the free consultation; they really listen.

Karen Spencer

Ordered beams for our vaulted great room. Needed extra long lengths and a distressed finish. Royal Foam said, “We can do that,” and delivered. The texture is top-notch. Delivery was fast, and the installation guide was super helpful. Now it feels like a mountain lodge!

Derek and Pam Hudson

Frequently Asked Questions

Blog Posts

Faux Wood Beams

A ceiling is not just a part of the project that gets closed off at the very end and forgotten. Very often the ceiling plays the role of a spatial divider and forms the first visual impression of the interior. In many cases, the ceiling is exactly where brand identity is expressed. It’s also the surface where engineering and design solutions can be combined - a place to hide mechanical systems that simply can’t be concealed any other way. And every time there is a request for a warm, wood-textured ceiling finish without structural complications or added load, the discussion inevitably touches on the same concerns: the weight of the construction, the level of maintenance required, and the risk of deformation over time. That is where modern faux ceiling beams step in as a real engineering tool, not just a decorative add-on. Instead of fighting material behavior on site, they get predictable, pre-engineered faux wood ceiling beams and faux celling beams ceiling kits that arrive already painted, sized to their drawings, and ready to install with standard tools.

A ceiling is not just a part of the project that gets closed off at the very end and forgotten. Very often the ceiling plays the role of a spatial divider and forms the first visual impression of the interior. In many cases, the ceiling is exactly where brand identity is expressed. It’s also the surface where engineering and design solutions can be combined - a place to hide mechanical systems that simply can’t be concealed any other way. And every time there is a request for a warm, wood-textured ceiling finish without structural complications or added load, the discussion inevitably touches on the same concerns: the weight of the construction, the level of maintenance required, and the risk of deformation over time. That is where modern faux ceiling beams step in as a real engineering tool, not just a decorative add-on. Instead of fighting material behavior on site, they get predictable, pre-engineered faux wood ceiling beams and faux celling beams ceiling kits that arrive already painted, sized to their drawings, and ready to install with standard tools.

What faux wood beams actually do in a project

Even though they are decorative and non structural, good wood faux beams work at several levels at once. We start from your CAD or BIM files and build a detailed 3D model that matches the project drawings, including vaulted angles, cut outs for sprinklers, diffusers and recessed cans. We generate the real wood texture, from rough sawn to nearly invisible grain for modern interiors. Over 25 years we have seen trends shift from heavy rustic to slim minimalist profiles, and we keep that whole range in our library.

Color is matched to your physical samples, not to a generic palette.

A lot of clients literally send a piece of flooring or cabinet door and ask us to match that tone. Beams are formed as U-shaped shells or solid look profiles depending on the task. Each beam is painted on our side.

You receive a fully finished product that does not need additional coating.

faux ceiling beams exterior

faux ceiling beams

- fire performance tested to the relevant ASTM standards for surface burning characteristics (for example, Class A or Class B per project requirements)

- documentation packages that help your team prove compliance with IBC and local amendments

- respect for NFPA requirements around sprinklers, clearances and access for maintenance

- clear definition that beams are decorative, non load bearing elements, which simplifies the engineering path and responsibility chain.

On commercial jobs in Miami and Atlanta our documentation sets have been used directly in communication with building officials. The fire marshals were less interested in the marketing description and much more in the data sheets, fire spread indexes and confirmation that the beams do not interfere with sprinkler coverage. That is exactly the level we prepare for.

For most ceiling applications, this is what tilts the decision toward best faux wood beams made from foam: you can predict how they will behave not just in the showroom, but in a real building with climate, maintenance staff and tenants.

Variants and ways to use faux wood beams

Vaulted ceilings and complex geometries

Design questions often start with something like how to install faux ceiling beams in vaulted ceiling without turning it into a structural nightmare. The practical advantage of architectural foam elements is in the combination of low weight, stable geometry, and full compliance with technical documentation, fire and safety regulations, and building standards. Once, we worked on a residential project near Jacksonville that featured a high vaulted ceiling in the great room. The unique challenge was the multi-level ceiling configuration: the roof pitch measured 36 degrees, the ridge line ran nearly 24 feet, and the ceiling heights varied significantly across different areas of the space. We collaborated closely with the project’s designer, who wanted the visual effect of traditional exposed trusses without introducing heavy structural components that would overload the design. For this project, we fabricated a system of intersecting faux wood beams ceiling profiles with pre-cut angle joints and concealed mounting hardware for all connection points. On site, the installation crew told us everything had been planned with exceptional precision - the drawings and technical documentation were clear and detailed, and the entire installation was completed in just one day. The inspection was approved on the first attempt, since the beams were classified as decorative, non-structural elements.

Kitchens and living spaces

Most often, kitchen faux wood ceiling beams or faux wood ceiling beams in living room are used to create a sense of warmth and real wood style, homeliness and visual balance - a harmonious, well-organized space.

Another project in Sarasota had a heavy, traditional wood kitchen, and the owner was afraid faux material would look fake. We matched the color to a 10 year old cherry cabinet door, reproduced a very specific cathedral grain pattern and created four modest faux beams in kitchen that visually tied the island to the perimeter cabinets. A year later the client wrote back saying nobody ever guessed the beams were not solid cherry.

Commercial and hospitality interiors

In commercial spaces, the main battle is often between the schedule and the need to look "custom". In downtown Atlanta a coffee chain needed large faux beams in a 14 ft high space, alongside exposed ductwork. Metal would make the place feel cold, and real timber would require extra structural coordination for each location. We provided a repeatable kit from faux beams & mouldings: U shaped beams, matching crown mouldings to terminate them at columns, and small trim to frame signage.

Exterior applications and porches

Outdoor use has its own set of challenges. Exterior faux beams must live with UV, wind and sometimes salty air. On a coastal house near Fort Myers we produced outdoor faux beams for a covered entry and a pergola facing the water. The engineer needed to keep most of the real structure in steel for wind load reasons, but the client wanted a warm "timber" appearance. Foam beams were wrapped around the steel profiles, with special end caps that imitated cut timber.

Three hurricane seasons later the beams keep their color and shape. The owner does not need to sand or stain anything, and the maintenance company simply washes them with water when they pressure wash the rest of the facade.

Doorways and transitions

Sometimes a simple faux beams doorway element solves a more complex zoning task. In an office fit out in Orlando the corridor into the collaboration area felt like an arbitrary opening in a wall. We created a 10 inch deep beam and two shallow side returns that formed a soft "portal" without building a full arch. The HR team later told us that staff actually referred to it as "the threshold" between focus work and team space. A small beam essentially set the tone for movement in the office.

Why this solution is technically and economically interesting

From a purely engineering view, Faux Wood Beams are attractive because they remove variables that usually cause headaches late in a project. When architectural elements are large and voluminous, this is where foam’s main advantage becomes clear. The geometry formed at the factory is inspected before shipping to ensure full compliance with all drawings and every specification agreed upon. As a result, the beams arrive on site exactly matching the plans and do not require trimming, reshaping or any additional preparation before installation. Foam beams are non-structural, which means they provide a purely decorative function and can also conceal wiring or other utilities, but they do not carry loads - that responsibility remains with the primary structural system. Foam architectural elements meet all fire-safety requirements and comply with applicable building and architectural codes and standards, with full documentation to confirm it. We supply complete technical and supporting documentation, including drawings, with every shipment of our architectural components.

Integration & Installation Efficiency

Our beams are designed to integrate seamlessly with lighting, sprinkler systems, and HVAC components. All coordination is planned in advance - before the architectural elements arrive on site.

Economic Advantages:

- Reduced installation time for trimming, fitting, unloading, and preparation

- Fewer change orders related to unforeseen ceiling conditions

- Reduced need for heavy access equipment (lifts, scaffolding)

- Minimal long-term maintenance - no staining cycles, no warping or cracking

- Predictable lead times that help keep project schedules on track

We see a pattern: clients who originally came to us "just to save a little on a single project" often return and standardize buy faux wood beams as their default solution on a whole category of jobs. For a residential developer around Tampa, shifting to foam beams cut call backs for ceiling issues almost to zero, which mattered more than the material line price. For a hospitality group in Georgia, standardizing ceiling assemblies across locations made their internal design guidelines stronger and faster to roll out. If you are evaluating options now, the practical step is simple: send us ceiling plans and a couple of photos of the space or mood board. We prepare a configuration of best faux wood beams with sizes, spacing and finish proposals, and then refine it together with your team until it works technically and visually.

Why it is safe to rely on Royal Foam US

Risk-Controlled Project Delivery

Working with ceiling elements is always about managing risk. For over 25 years, we have built our process around minimizing uncertainty at every stage.

- Made in the USA with in-house production - no anonymous intermediaries

- Custom fabrication, from one-of-a-kind profiles to repeatable series for multi-location projects

- Delivered fully assembled and finished, reducing on-site labor and installation time

- Dedicated project manager familiar with your drawings and tracking all revisions

- Engineering flexibility for projects ranging from residential spaces to large public environments

- Budget flexibility - from standard profiles to complex, custom-designed beams

- Fast, accurate estimates - often within minutes once drawings are reviewed

Logistics & Storage

At our warehouse located near the production facility, we offer complimentary storage if your jobsite is not yet ready for installation. This helps avoid delivery congestion and eliminates the need for temporary on-site storage.

Our logistics process is fully transparent. We coordinate directly with long-term, trusted transportation partners and can arrange delivery of all types of cargo, including oversized shipments.

Integration & Installation Efficiency

Our beams are designed to integrate seamlessly with lighting, sprinkler systems, and HVAC components. All coordination is planned in advance—before the architectural elements arrive on site.

- Reduced installation time for trimming, fitting, unloading, and preparation

- Fewer change orders related to unforeseen ceiling conditions

- Reduced need for heavy access equipment (lifts, scaffolding)

- Minimal long-term maintenance - no staining cycles, no warping or cracking

- Predictable lead times that help keep project schedules on track

- Sustainability & Technical Support

- Environmentally conscious production using modern, energy-efficient materials and processes

- Technical support from concept development through shop drawings and post-installation

- 20-year warranty covering structural integrity and finish, when products are properly installed and maintained

Client Experience & Collaboration

We provide physical samples and 3D mock-ups, allowing clients to evaluate materials in advance, understand the final architectural outcome, and make informed decisions regarding color, texture, grain, and geometry.