Who Is This Solution For

Faux Wood Trusses That Transform Any Space

Faux wood trusses add dramatic architectural presence without the weight, cost, or engineering challenges of real timber. They install easily, making it possible to achieve bold ceiling designs even in spaces where natural wood isn’t practical. With realistic grain textures and multiple styles available, they complement both modern and traditional interiors. The material resists moisture, temperature changes, and warping—offering long-lasting beauty with virtually no maintenance. With Faux Wood Trusses, you get design freedom, fast installation, and standout style that transforms the room instantly.

Faux Wood Trusses That Transform Any Space

Faux wood trusses add dramatic architectural presence without the weight, cost, or engineering challenges of real timber. They install easily, making it possible to achieve bold ceiling designs even in spaces where natural wood isn’t practical. With realistic grain textures and multiple styles available, they complement both modern and traditional interiors. The material resists moisture, temperature changes, and warping—offering long-lasting beauty with virtually no maintenance. With Faux Wood Trusses, you get design freedom, fast installation, and standout style that transforms the room instantly.

Faux Wood Trusses That Transform Any Space

Faux wood trusses add dramatic architectural presence without the weight, cost, or engineering challenges of real timber. They install easily, making it possible to achieve bold ceiling designs even in spaces where natural wood isn’t practical. With realistic grain textures and multiple styles available, they complement both modern and traditional interiors. The material resists moisture, temperature changes, and warping—offering long-lasting beauty with virtually no maintenance. With Faux Wood Trusses, you get design freedom, fast installation, and standout style that transforms the room instantly.

How We Work

How to Order From Royal Foam

Step 1. Ready design

We adapt it for production and installation, preserving every detail.

Step 2. Define your vision

Capture a clear picture of the client’s ideas before moving to design and rendering.

Step 3. Plan specifications

Outline measurements, production methods, and finalize materials, components, and finishes.

Step 4. Installation

Our team ensures precise setup, perfectly aligning your custom surround with the space.

Step 1

The aim of this step is to capture a precise picture of the client’s vision before proceeding to technical design and visual rendering.

Step 2

During this phase, we define the specifications, production methods, and measurements, while finalizing the look by selecting materials, elements, and finishes.

Step 3

Once fabrication is complete, our installation team will handle every aspect of the setup, ensuring your custom surround is fitted with accuracy and seamlessly integrated into your space.

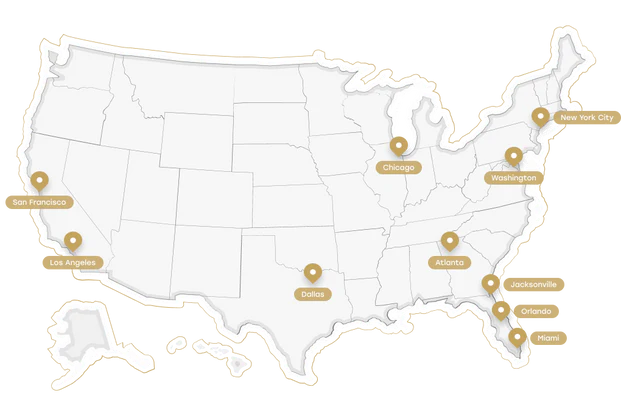

Areas We Serve

We proudly serve clients across the United States, including major cities such as

· Jacksonville · Orlando · Miami · Atlanta · Dallas · Los Angeles · New York City · Chicago · Washington · San Francisco ·

Companies We Serve

Testimonials

I highly recommend the services of Royal Foam because they are always consistent with their quality of 3D letterings and other products.

Samuel Ridge

Thank You Royal Foam for providing me with the gorgeously designed monument sign I had ordered for my newly opened company.

Danial Bryan

After installing an arch from Royal Foam not only the look has improved but also my home has become a lot more spacious. I suggest and thank Royal Foam. I will contact again to Royal foam for my new arch work at my home. Designs are very good and finishing is also good.

Amy Corey

I had ordered plastic letters to put up in front of my Company and I’m thanks to the quality, come rain or sun, they shine like new always. Thank you for such good products Royal Foam.

Origin Teak

Frequently Asked Questions

Blog posts

Faux Wood Trusses

Faux Wood Trusses: When Design Meets Common Sense

Picture this. You walk into a mountain lodge in Colorado, or maybe a boutique winery out in Sonoma. Or even a converted warehouse apartment in downtown Dallas. What’s the first thing your eyes do? They wander upward. And what’s waiting overhead is almost always the same: strong lines, a rhythm of beams that tie the whole space together. The surprise? Most of the time, those beams aren’t timber at all. They’re faux wood trusses.

People stop under them, tilt their heads back, and whisper: “Wow, those beams are stunning.” Some even reach up, tap them with their knuckles, and then shoot that look — “No way these are fake.” But yes, they are. And that’s the beauty. You get the look, the weight of history, the craftsmanship — without the pests, without the endless maintenance, and without the crushing costs that real wood brings.

Why People Keep Turning to Faux Wood Trusses

Let’s not sugarcoat it: real wood trusses are gorgeous. They smell like pine in the sun, they creak with character, and they make a brand-new home feel as if it’s been standing for a hundred years. However, they also come with baggage.

Weight. Real timbers are heavy — so heavy they strain foundations.

Logistics. Deliveries mean cranes, blocked streets, and entire crews waiting.

Movement. Wood shifts with the seasons — gaps in January, swelling in July.

Insects. Termites, beetles, carpenter ants… they love wood more than you do.

Faux wood trusses sidestep all of that. Consequently, two installers can carry what would take five men with oak. Humidity won’t twist them. They don’t invite termites to dinner. And the budget? Predictable — therefore no “surprise” invoices months later.

The Magic: How Faux Wood Beams Change a Room

It’s not just about saving money or making life easier. Instead, the real magic is how they change the feel of a room. We’ve seen restaurants where the ceiling — not the food — became the most photographed thing on Instagram. We’ve seen living rooms suddenly feel warmer, almost like they’re giving the family a hug. One couple even told us: “We spend more evenings together now. The ceiling makes the room feel alive.”

That’s not an exaggeration. Once the trusses go up, the atmosphere changes. Period.

The Truth About “Faux”

Not long ago, “faux” meant second-rate. Fake. Something you bought because you couldn’t afford the real deal. But now, step under today’s faux wood beam trusses and the illusion wins.

Every grain, every ridge, every tiny saw mark is cast from actual wood. In fact, the eye buys it instantly. The hand buys it too. Even old-school carpenters — the kind who can spot oak from across a room — often run their fingers across a truss and laugh: “If I hadn’t installed this myself, I’d swear it was timber.”

Unlike natural beams, these won’t crack without warning, sag with age, or darken into shades you never asked for. Instead, they stay as they are: believable, reliable, beautiful.

Where They Really Shine

-

Cabins that want a rustic soul without structural stress

-

Lofts that feel cold until espresso-dark beams warm the space

-

Restaurants where atmosphere matters as much as the menu

-

Outdoor spaces — porches, pergolas, patios — where wood usually fails

One chef nailed it: “If the beams stay beautiful without me worrying, I can focus on the food.” That, ultimately, is a trade worth making.

Custom Faux Wood Trusses: Because One Size Never Fits All

King Post: bold, ceremonial, an architectural handshake.

Queen Post: balanced, elegant, almost musical.

Scissor Trusses: cathedral lift without cathedral drama.

Hammerbeam: the showstoppers — they stop guests cold.

And finishes? They make all the difference. Driftwood gray for coastal calm. Deep espresso to ground a modern loft. Barnwood gray that convinces guests the beams came from a century-old barn. Meanwhile, walnut tones feel timeless and warm.

We once had a client bring an old carved mantelpiece and say: “Match this.” The trusses went up, and the entire house suddenly felt like it was singing in tune. That is what custom design does — it turns beams into storytelling.

Commercial Projects: When Ceilings Become Identity

At home, trusses bring warmth. However, in business, they create memory.

A winery in California wanted aged beams but feared termites. Faux delivered.

A city restaurant needed rustic charm without downtime. Faux solved it.

A resort hotel wanted grandeur without stressing marble floors. Faux made it possible.

Guests don’t just remember the meals or the check-in. They remember the ceiling. That’s branding you can’t replicate any other way.

Real vs. Faux Wood Trusses

Let’s keep it straight:

Real wood trusses: historic, structural, authentic — but heavy, expensive, high-maintenance.

Faux wood trusses: decorative, lightweight, budget-friendly, low-maintenance — and authentic in appearance.

Unless your roof depends on real timber, faux wood trusses are almost always the smarter choice.

A Historian’s Note

Romans spanned basilicas with timber frames. Medieval England gave us hammerbeam halls. Japanese temples curved cedar into poetry. American colonists raised barns with oak skeletons.

Wood trusses were never just supports. They were culture, craft, identity. Today, faux trusses keep that heritage alive — giving modern spaces the same rhythm without the medieval headaches.

Hidden Bonuses Nobody Expects

Clients call months later to share discoveries:

-

Rooms feel quieter — echoes die down.

-

Morning light turns beams into sculpture; evening lights turn them into art.

-

Faux doesn’t radiate heat — it only looks warm.

-

No strange smells.

-

From salty coasts to snowy mountains, they hold steady.

-

Eco-friendly bonus: fewer old forests cut down.

These “little things,” therefore, often become the biggest reasons people fall in love with them.

Light + Faux Wood Trusses = Atmosphere

Light is theater. Natural sun skims the grain by day. At night, uplights turn joints into sculpture. We’ve seen couples toast anniversaries under glowing beams. Restaurants triple their tagged photos after lighting upgrades.

One rule: install dimmers. Always.

Working With Designers and Contractors

Design is part choreography, part diplomacy. Architects sketch. Designers debate palettes. Owners stress about budgets. Meanwhile, our job is to translate. Show how trusses align with fireplaces, how finishes tie into cabinetry, how shadows fall.

Contractors appreciate it. One joked: “You guys are like ceiling traffic cops.” He wasn’t wrong.

Strength Without Stress

Real oak looks strong — and is. But, it stresses everything around it. Homeowners sometimes admit they can’t sleep during storms, afraid beams might sag.

Faux trusses eliminate that fear. They give permanence without pressure.

America’s Way of Building

From desert Arizona to snowy Vermont, Americans want bold design without upkeep.

-

In Arizona, mission-style homes needed arches and trusses — but timber warped. Faux saved the look.

-

In Vermont, a ski lodge wanted tradition but feared snow load. Faux again delivered.

Different climates, same result.

The Small-Space Surprise

Not every home has cathedral ceilings. One ranch had eight-foot ceilings. Owners feared beams would shrink the room. Solution? Slim profiles, lighter finishes.

Surprisingly, the room felt taller. Sometimes the right lines add air rather than steal it.

Architecture That Changes Behavior

This isn’t just about looks. It’s about how people live. Families gather more. Kids do homework in the kitchen. Dinners last longer. One homeowner said it perfectly: “We didn’t just buy faux wood trusses. We bought the atmosphere.”

The Future of Faux

Finishes sharpen yearly. Profiles expand. Hybrid designs now wrap steel in faux wood for strength and authenticity.

The future? Spaces that feel historic without cutting historic trees.

Life After Install

Week one: You can’t stop looking up.

Six months: You forget — but host more.

One year: Still flawless.

Five years: Paint may change, furniture may change — the ceiling stays the anchor.

One client said: “The trusses are the one design choice I’ve never regretted.”

Design Tips That Actually Work

-

Match trusses to floors or cabinetry for harmony.

-

Don’t chase perfection — imperfections sell the illusion.

-

Plan lighting before beams go in.

-

Add one hero detail — people will ask every time.

Faux wood trusses aren’t a compromise. Instead, they’re evolution. They take the language of wood — history, rhythm, presence — and translate it into modern design without the drawbacks. From a ranch in Texas to a hotel lobby in Chicago, ceilings with faux wood beams don’t just cover a room.

They complete it.