Our custom sandblasted signs are wholesale as we rely on you to provide your design and sales while we do the manufacturing.

By providing a custom area within our website, retail sign companies can expand their product line by using our shop as their manufacturing facility.

When it comes to the art of sandblasted sign making, we’ve got it covered! We can provide virtually any product imaginable that is being used to direct traffic, ensure safety, or brand your business.

Whether you are looking to by sandblasted signage for office, sandblasted signs for a residence, entrance sandblasted signs,development directional signs, business park tenant signs, lobby or reception displays, custom signs for a business, church reader boards or golf course signage, marketing sign we can provide a solution that will exceed your expectations. It is our focus to produce ‘made to order’ signs that DEMAND ATTENTION, and define a sense of taste that will make a lasting impression.

Add 3d Objects To Beautify Your Sandblasted Signs And Define Your Brand!

Our sandblasted signage and sign accents are manufactured using a wide variety of materials such as wood, sign foam, HDU, PVC, glass, stone, tile, marble, brushed and mill finish metals, vinyl, MDO and MDF. Our services utilize the best suited material combinations for each project. This allows us to provide signage solutions that fit your budget and needs.

Companies We Serve

We are happy to offer sandblasted signs, decorative 3 Dimensional objects and accents.

From now on you can beautify your sandblasted signs with a various selection of decorative elements. Such elements work perfectly for commercial signage and residential community signs. Good examples are legal services office custom signs, building number plaques, traffic management signs, community entry signs, church signs etc.

Who Is This Solution For?

HDU Royal Foam can be sandblasted with several different patterns.

The most common two are wood grain and sandstone. At Royal Foam, we do our best to make the process of designing and building your custom sandblasted signs and logo as easy, convenient, and enjoyable as possible.

How We Build Your Custom Sandblasted Signs

The sandblasted signs build process begins with your quote request. We’ll respond by asking you a number of questions to help us understand what type of custom sandblasted signs will meet your needs and budget. Once we have a clear idea of your needs, we’ll email you a written estimate describing the signs we will build for you and giving you the exact price for the signage project. All you need to do at this stage is sign and return the estimate and make a deposit (by mailing a check or card by phone). After this step is done, we can begin designing and building sandblasted signs for you.

Whether you provide us finished artwork or we design the sandblasted signs for you, we always make sure that you review and approve the sign layouts before we begin construction. Once your signs have been manufactured, we schedule a delivery or you can pick them up at our office.

How to submit your artwok

We work with a broad array of artwork formats, including everything from hand-drawn sketches to vectorized files that you email to us. The most efficient (and therefore most cost-effective) format is vectorized artwork, in an .eps or .ai format. Please ensure that all text is converted to outlines. If you are not able to convert text to outlines, check with us to see whether you’re using one of the hundreds of fonts we have on file. If vector art is not available, we can nearly always scan and digitize your logo for a minimal charge If you don’t have an artwork, our designers will be happy to help you with a custom layout for your project.

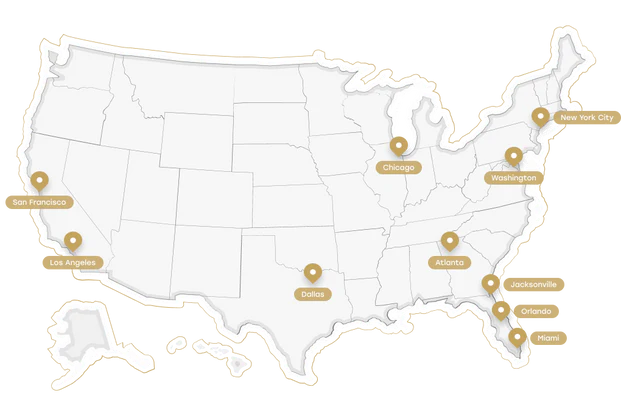

Areas We Service

We proudly serve clients across the United States, including major cities such as

USA: · Jacksonville · Orlando · Miami · Atlanta · Dallas · Los Angeles · New York City · Chicago · Washington · San Francisco ·

How to Order From Royal Foam

Step 1. Ready design

We adapt it for production and installation, preserving every detail.

Step 2. Define your vision

Capture a clear picture of the client’s ideas before moving to design and rendering.

Step 3. Plan specifications

Outline measurements, production methods, and finalize materials, components, and finishes.

Step 4. Installation

Our team ensures precise setup, perfectly aligning your custom surround with the space.

Step 1

The aim of this step is to capture a precise picture of the client’s vision before proceeding to technical design and visual rendering.

Step 2

During this phase, we define the specifications, production methods, and measurements, while finalizing the look by selecting materials, elements, and finishes.

Step 3

Once fabrication is complete, our installation team will handle every aspect of the setup, ensuring your custom surround is fitted with accuracy and seamlessly integrated into your space.

Testimonials

I highly recommend the services of Royal Foam because they are always consistent with their quality of 3D letterings and other products.

Samuel Ridge

Thank You Royal Foam for providing me with the gorgeously designed monument sign I had ordered for my newly opened company.

Danial Bryan

After installing an arch from Royal Foam not only the look has improved but also my home has become a lot more spacious. I suggest and thank Royal Foam. I will contact again to Royal foam for my new arch work at my home. Designs are very good and finishing is also good.

Amy Corey

I had ordered plastic letters to put up in front of my Company and I’m thanks to the quality, come rain or sun, they shine like new always. Thank you for such good products Royal Foam.

Origin Teak

Frequently Asked Questions

Blog posts

-

Royal Foam US Receives 2023 Best of Jacksonville Award

Read nowPress Release FOR IMMEDIATE RELEASE Royal Foam US Receives 2023 Best of Jacksonville Award Jacksonville Award Program Honors the Achievement JACKSONVILLE April 20, 2023 -- Royal Foam US has been selected for the 2023 Best of Jacksonville Award in the...

-

-

2022 BEST OF JACKSONVILLE AWARD

Read nowAugust 16, 2022 - Royal Foam US has been selected for the 2022 Best of Jacksonville Award in the Architectural Designer category by the Jacksonville Award Program.

Sandblasted Signs

There’s a point on every project when everything still feels temporary. Dust hangs in the air. Cables snake across the pavement. Someone’s arguing with a lift that won’t start.

Then the sandblasted signs roll off the truck.

And just like that, the site stops looking like a job and starts looking like a place. Corners line up. Shadows fall right. People who’ve been pushing twelve-hour days suddenly stand still for a moment. It’s hard to explain, but it happens almost every time.

It isn’t about decoration. It’s about closure — and about confidence that this place will stand the test of time.

The Craft Beneath the Texture

Sandblasted signs might look straightforward: raised letters, recessed field, some paint. In practice, they’re the sum of dozens of small decisions that either make them work or quietly undermine them.

We start with CAD layouts tighter than they probably need to be, and we do it on purpose. If kerning drifts here, you pay for it later when a crew has to re-space a whole line of copy in the field. We’ve seen it happen — and no one forgets the day they had to fix lettering at height with a heat gun.

After layout comes masking: blast-resistant stencil plotted, applied, and sealed at the edges. Even a 1 mm lift lets grit creep under and fuzz the edge. We check every corner under raking light before anyone even touches the blast booth trigger.

Blasting isn’t mindless either. We run 60-mesh aluminum oxide — aggressive enough to bite, fine enough to keep edges clean. Experienced hands don’t just watch gauges; they listen. The pitch shifts as the grit digs deeper. You can feel through the gloves when it’s time to stop.

Relief depth is what makes them work. Depth throws shadow, shadow builds contrast, and contrast equals legibility when glare or dusk flatten everything else. Even a flat color looks confident when it carries texture. We say this a lot — and we keep saying it, because people underestimate how much those shadows matter.

Materials That Actually Hold Up

Materials set not just the look, but the lifespan, the installation method, even the stress level of the crew. We don’t treat them as an afterthought.

High-Density Urethane (HDU)

Our everyday choice. No grain, which means crisp edges after blasting. Waterproof, dimensionally stable, and light enough that two installers can carry a full panel without rigging. It shrugs off freeze–thaw cycles and doesn’t swell or rot. Honestly, we were skeptical of our first coastal job — salt air ruins everything. A decade later, those panels still read clean.

Cedar or Redwood

Warm, honest texture. Perfect for heritage districts or boutique hotels. They demand sealing and periodic care — fair trade, if the setting calls for real grain. We’ve tried imitations. They don’t work.

Sandblasted stone signs

The permanent answer. Heavy, slow, and expensive up front — but they outlast everything. We’ve watched stone monuments stay sharp decades after the buildings behind them were replaced. When permanence matters more than speed, stone wins.

Each of these has its place. The trick is matching the material to the life cycle of the site — and to how much disruption you can afford during install.

What the Cost of Sandblasted Signs Really Covers

People often ask for a number. A clean figure for the cost of sandblasted signs. The truth is more nuanced.

HDU lands mid-range on the scale. Cedar and redwood cost more to finish and maintain. Sandblasted stone signs sit at the high end because of their sheer weight and the rigging they demand.

Labor shifts the curve too. HDU spends more time in the shop, almost none in the field. Stone spends less in the booth but more on cranes, permits, and footings.

We’ve seen budgets leak not from big-ticket items but from chaos: a crane rescheduled, a landscaping crew sent home early, a last-minute traffic control permit. HDU avoids most of that. Stone rarely does.

Then there’s lifespan. HDU often runs ten to fifteen years before its first refresh. Stone can last for generations. The repaint cycle matters too — eight to ten years for HDU versus two to three for flat printed panels. Those differences stack quietly until they become decisive.

We watched a hospital campus cut total spend by nearly half when they switched from cast stone to HDU. Install time halved. Eight years later, no repaint yet. It’s one of those results that sounds like luck, but it’s just the math of fewer moving parts.

Design Pitfalls We’ve Learned to Avoid

- Thin strokes die in blasting or the first freeze. Bold weights live.

- Tight counters trap grit and blur edges. Letters need breathing room.

- Small copy gets shallow cuts; large faces need deeper relief for shadow at distance.

- High-contrast solids beat gradients — gradients fade or disappear.

- Cap height must match viewing distance; a tiny type on a road monument is invisible.

- Side lighting makes relief sing. Overhead floods flatten it.

- Drivers scan high and early. Pedestrians scan low and late. Sightlines matter.

We’ve watched flawless sandblasted signs vanish behind new shrubs because no one walked the sightline before fabrication. It still stings — and it still happens when people rush.

Comparing to Flat or Routed Panels

Flat prints are quick, but fade fast and need constant replacement. Routed acrylic or metal can look sharp but often feel temporary, like placeholders.

Sandblasted signs do the opposite. Depth throws shadow. Shadow builds contrast. Contrast holds attention. They age slowly and quietly. They feel anchored to the site. That sense of permanence has real value, especially when a project needs public trust.

And honestly, once people see them in place, they rarely want to go back.

Installation and Maintenance in Practice

We build for fast mounting. Threaded inserts or concealed cleats go in before paint. Panels ship crated and labeled to match plan callouts. Crews lift, level, bolt, and move on. No welding in parking lots. No cutting brackets on tailgates.

Maintenance is just as uneventful. Rinse them now and then. Refresh the UV topcoat every eight to ten years. Weather rarely kills these. Forklifts do.

Where They Actually Work

We see sandblasted signs thrive anywhere permanence matters.

- Monument signs at main entries, framed by landscaping and low uplighting.

- Sandblasted stone signs at civic gateways, campuses, and memorials — slow to install but measured in decades.

- Wall-mounted HDU panels adding depth to façades without demanding heavy structure.

- Wayfinding systems on trails, parks, and campuses, where weather and traffic never stop.

Once you notice them, they’re everywhere — resorts, hospitals, corporate parks, botanical gardens, heritage retail streets. They quietly make places feel finished. We keep saying “quietly” because that’s their trick — they don’t shout, they settle in.

A Few Real Projects

Hotel entry, impossible deadline. Another fabricator missed their ship date. We pivoted to HDU, embedded hardware in-shop, and a two-person crew installed overnight. Six winters later: still no repaint.

City park upgrade, budget squeeze. The spec called for sandblasted stone signs, but crane time broke the budget. We built stone bases with HDU faces on concealed frames. They read as solid stone, but install time halved and cost dropped about 40%.

Corporate campus, minimalist brand. The brief demanded deep relief and matte neutrality. We blasted HDU to 15 mm, finished it with low-gloss architectural polyurethane, and floated panels on hidden brackets. They looked like cast concrete and went up in hours.

These jobs taught us something we keep relearning: getting the right material early saves more pain than almost anything else you can do.

Coordination, Logistics, and Timelines — The Hidden Half of Success

People often talk about sandblasted signs as if they’re just decorative. On real construction sites, they’re mostly about logic and scheduling. We didn’t learn that on easy projects — and we didn’t forget it afterward.

The key thing is: they arrive fully finished. No field painting, no cutting brackets on a truck bed, no messing with adhesives in freezing weather. That means we can drop them into the schedule right at the end, when every day is already booked down to the hour and no one wants to reschedule landscapers, cleaners, or final inspections. We once delivered a full sign package for a retail arcade where the client gave us three overnight windows between cleaning crews and a city commission visit. It worked because everything showed up labeled, with embedded hardware, and the crew simply lifted and bolted them in place — no sparks, no welding, no drama.

Then there’s shipping and storage. Stone monuments need exact timing — cranes, rigging, staging space. HDU can arrive early, sit quietly in their crates, and wait a week or more without trouble. On congested urban sites, that flexibility matters more than people expect. Honestly, it saves more schedules than the carving itself.

And the third piece — permits and access. Lightweight panels skip a lot of red tape. No lane closures, no hot-work permits, no separate safety sign-offs for lifting gear. On paper, those line items look small. In practice, they’re often what pushes an install back a week and creates a domino effect. We’ve seen one delayed permit derail an entire finish sequence. HDU sandblasted signs act like a safety net — giving just enough control to keep the schedule from unraveling.

Why Working With Us Pays Off

Budgets rarely fail in one dramatic crash. They leak — through small bursts of chaos.

We frontload discipline to stop that. Precision in design. Method in the shop. Predictable crates at install. That reliability doesn’t show up as a line item, but you feel it when the job stops throwing surprises at you.

Funny thing is, the same GCs who doubt sandblasted signs on the first project usually ask for them on the next one.