We produce custom Architectural Cornices All Style

Depending on the profile, material, and finish used, cornice can warm a room up or give it cool, commanding elegance. They can hide flaws or highlight virtues. When made correctly and used intelligently, there’s almost nothing Decorative Architectural Shapes Cornices can’t do.

Decorative Architectural Cornices: Effortless Installation and Stunning Design Impact

As easy to install and affordable as they are, Decorative Architectural Shapes Cornices bring tremendous beauty, even glamor to homes, hotels, restaurants, and other spaces. Cornices draw the eye where the designer or architect wants it to go. A dramatically high ceiling, a charming set of French doors, or even a spectacular view can be emphasized with the artful use of cornices.

Designers will appreciate our cornices. Decorative Architectural Shapes has a huge variety of designs and finishes, as well. You’ll find plenty of interesting profiles at Decorative Architectural Shapes. With your imagination and our suggestions, who knows what you might create?

Decorative Architectural Shapes Cornices are great for framing your rooms, implementing your ideas. Such kinds of frames will make your interior finished, bring a design touch to your home.

Who Is This Solution For?

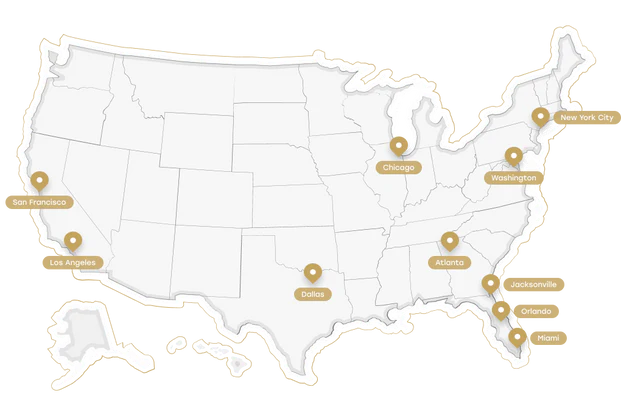

Areas We Service

We proudly serve clients across the United States, including major cities such as

USA: · Jacksonville · Orlando · Miami · Atlanta · Dallas · Los Angeles · New York City · Chicago · Washington · San Francisco ·

Solutions For Timeless Architecture And Contemporary Living

How to Order from Royal Foam

Step 1. Ready design

We adapt it for production and installation, preserving every detail.

Step 2. Define your vision

Capture a clear picture of the client’s ideas before moving to design and rendering.

Step 3. Plan specifications

Outline measurements, production methods, and finalize materials, components, and finishes.

Step 4. Installation

Our team ensures precise setup, perfectly aligning your custom surround with the space.

Step 1

The aim of this step is to capture a precise picture of the client’s vision before proceeding to technical design and visual rendering.

Step 2

During this phase, we define the specifications, production methods, and measurements, while finalizing the look by selecting materials, elements, and finishes.

Step 3

Once fabrication is complete, our installation team will handle every aspect of the setup, ensuring your custom surround is fitted with accuracy and seamlessly integrated into your space.

Companies We Serve

Testimonials

The use of decorative elements allows you to place emphasis on both the facade and the interior.

Samuel Ridge

Thank You Royal Foam for providing me with the gorgeously designed monument sign I had ordered for my newly opened company.

Danial Bryan

I had ordered plastic letters to put up in front of my Company and I’m thanks to the quality, come rain or sun, they shine like new always. Thank you for such good products Royal Foam.

Origin Teak

After installing an arch from Royal Foam not only the look has improved but also my home has become a lot more spacious. I suggest and thank Royal Foam. I will contact again to Royal foam for my new arch work at my home. Designs are very good and finishing is also good.

Amy Corey

Frequently Asked Questions

Blog posts

-

Royal Foam US Receives 2023 Best of Jacksonville Award

Read nowPress Release FOR IMMEDIATE RELEASE Royal Foam US Receives 2023 Best of Jacksonville Award Jacksonville Award Program Honors the Achievement JACKSONVILLE April 20, 2023 -- Royal Foam US has been selected for the 2023 Best of Jacksonville Award in the...

-

-

2022 BEST OF JACKSONVILLE AWARD

Read nowAugust 16, 2022 - Royal Foam US has been selected for the 2022 Best of Jacksonville Award in the Architectural Designer category by the Jacksonville Award Program.

Exterior cornice

Premium-class residential buildings, historic-style buildings, and public institutions - all of them require certain architectural elements. There are no small details here: every detail must fit into the chosen style. The most striking way to emphasize the chosen style is with exterior cornices - refined and ornate, yet lightweight and durable thanks to the use of ultra-modern EPS foam material.

Royal Foam's products deliver premium aesthetics, offering over 100 precision-crafted designs for commercial and residential applications. From exterior cornice molding to custom stucco cornice profiles, our lightweight solutions eliminate traditional installation complexities while maintaining the exquisite appearance that defines quality architecture.

Cornices in modern buildings

Cornice exterior elements serve as the defining architectural feature that connects building walls to the roof line. These horizontal decorative bands create natural-looking breaks, depth, shadow lines, and a professional look to any structure.

Traditional natural stone and concrete cornices were wrought with built-in issues, including structural weight requirements, complicated installation routines, and upkeep. Modern exterior foam cornice technology overcomes these challenges without compromising on classical design integrity.

That's why you can't do without cornice systems when finishing a house:

- They visually enhance the overall appearance due to the complex play of shadows and volumetric depth

- Protect the building from excess moisture by directing precipitation water away from wall-roof transitions

- Thanks to the flexible design, you can adapt the structure to various building styles

- They allow you to economically update the facade without making changes to the structure.

Modern EPS foam manufacturing enables accurate reproduction of traditional profiles, providing superior installation characteristics and long-term durability.

Stucco cornice lines and design options

Royal Foam manufactures a wide range of stucco cornices, covering both traditional and contemporary architectural styles. Our CRC series includes over 30 standard models. Custom sizes are also available.

Traditional cornices

This is a subtle nod to history, expressed in majestic horizontals. Classic cornices are inspired by Greek and Roman architectural traditions. They can be decorated with quatrefoils, acanthus leaves (ancient Greek hero ornament), and meander patterns (ancient symbol of luck and wealth).

Also in the catalog are multi-tiered structures with characteristic decorative elements of the ancient era. These cornices are suitable for historic renovation projects, public buildings, luxury homes, and commercial properties that require exquisite architectural detailing.

Contemporary linear cornice designs

Modern exterior cornices feature clean geometric profiles that complement today's architectural styles. Repeating motifs in the form of raised arches or convex rectangles attract attention without being irritating to the eye. Commercial buildings, modern residential projects, and retail spaces often use these streamlined profiles to enhance the appearance.

Custom foam cornices: superpower of design

Special project requirements often demand unique exterior cornice solutions. Royal Foam's manufacturing capabilities include the development of custom profiles based on architectural drawings or site measurements. This service is especially beneficial for those who are involved in restoration projects of historic buildings. EPS foam processing technologies allow for the most accurate reproduction of the original finish details - even if these are numerous baroque swirls.

Applications and building types: where stucco cornices are needed

Cornice exterior installations span broad groups of building types, each with specific performance and aesthetic needs. Royal Foam's range of products is designed to address various architectural needs while delivering consistent quality standards. Our specialists will help you select the right profiles for specific applications, so that they not only last long, but also look elegant and appropriate.

Residential buildings

Single-family residences quite literally get a new look after the installation of stucco cornices. These more refined touches augment not only the exterior's beauty, but the value of the property as well. This holds for both new constructions and remodels: EPS cornice systems are installed without altering the building whatsoever.

Multi-family building complexes often demand the same-profile requirements per several units, ensuring architectural homogeneity while keeping costs through bulk purchasing advantages.

Commercial and institutional projects

Office structures frequently recommend foam cornice systems for business facade enhancement without the cost and weight of traditional materials. A retrofit application particularly benefits from light properties.

Schools, hospitals, and government facilities require strong, minimal-maintenance exterior cornice solutions with the potential for heavy use while continuing to maintain professional appearance standards.

Why EPS foam cornices are the optimal choice for your design

Concrete, natural stone, or gypsum have been traditional cornice materials at various times. However, the existence of such a revolutionary material as EPS foam is forcing contractors to reconsider their priorities.

This material is much more suitable for outdoor use because of its exceptional performance characteristics:

- Excellent moisture resistance - due to the closed-cell foam structure and encapsulating polyurea hard coat, it is difficult for water to physically penetrate inside the cornice

- Ability to maintain structural integrity during freeze-and-thaw cycles without cracking or deterioration - don’t worry about unpleasant surprises in the mid-season

- Shock-resistant properties - thanks to a special encapsulating material, EPS can withstand even intense impacts

- UV resistance

- Using high-end exterior paint ensures long-term color retention.

And of course, expanded polystyrene does not deform, crack, or deteriorate under normal weather conditions.

Weight and installation benefits

Traditional stucco cornice molding installations often require structural reinforcement due to material weight. Our EPS solutions weigh 98% less than stone equivalents, enabling them to be installed on structures not rated for heavy architectural elements.

Also, standard tools are sufficient for cutting, shaping, and fitting operations. No specialized equipment or extensive structural modifications are required, and it significantly reduces labor costs and installation timeframes. If desired, the homeowner can even install our foam cornices themselves. If they opt for hiring a professional contractor, Royal Foam can suggest a local professional.

Cornice installation methods and technical support

Professional installation of EPS cornice boards for building perimeter requires proper preparation. Royal Foam provides comprehensive technical support, including detailed specifications and installation guidelines.

Usually sections of cornice can be simply glued to a wall using a special polymer composition for outdoor work that does not contain acetone (e.g., liquid nails). Standard construction tools are suitable for all cutting and fitting operations.

A step towards DIY-craftsmen

Smaller exterior cornice projects often accommodate owner installation with proper guidance and support. Our technical support team provides installation assistance via phone consultation at (855) EPS-FOAM. Detailed installation guides and video resources ensure the successful completion of DIY projects while maintaining warranty coverage and quality standards.

Help with professional installation

Though for large-scale projects, the help of professional installers might be necessary. These professionals have a good understanding of EPS characteristics and know the correct finishing methods to ensure long-term performance.

If you are at a loss as to who to contact, our specialists will be happy to be your "navigator" in this matter. We have foster contacts with installation professionals nationwide. Project consulting services help to determine appropriate fastening methods, substrate preparation requirements, and finishing characteristics for specific applications.

Why Royal Foam exterior foam cornices are worth choosing

There are no trifles in architectural design. Every element, even the seemingly inconspicuous one, shapes the character of the building, giving it uniqueness. And Royal Foam, as a company with 20+ years of experience, understands this uniqueness especially well. Here are the main facts illustrating our experience and quality:

- Jacksonville-based manufacturing facility produces all exterior cornices using high-precision CNC equipment and quality control protocols

- Hand-machined parts ensure consistent profile accuracy at all production stages

- Our 2022 and 2023 Best of Jacksonville Award recognitions reflect our commitment to manufacturing excellence and customer satisfaction

- Strict quality tests (including simulated tornadoes) validate the performance characteristics of materials and dimensional accuracy before shipping.

Standard cornice exterior profiles ship within established time frames, while custom projects require additional time depending on their complexity. Nationwide delivery is available regardless of project location.

Customer service specialists are available to advise on projects, assist with specification selection, and coordinate delivery via a dedicated phone number (855) EPS-FOAM.