What We Do

At Royal Foam, we see it this way: every idea deserves a chance to be brought to life. Whether it’s a finished drawing, a quick sketch, or simply a picture you’re carrying in your mind, we offer custom solutions that turn your concept into reality. And if you don’t have a clear idea yet, we’ll help shape one for you based on the information you share about your project.

These aren’t just standard foam-cut architectural pieces. We pay close attention not only to proportions, but to the design itself — the custom design — the lines, the form, the visual balance, and all the small details that ultimately shape the character of each element and the architectural expression of the building as a whole.

Our components install cleanly and easily with adhesive, regardless of whether it's a coffered ceiling or window surrounds. They look premium and add a distinctive character to the façade. And whether the project calls for a Baroque influence or coffered ceiling with a modern aesthetic, we apply the right texture, color, and design features so the architectural elements always appear refined, elevated, and visually striking. We mix form, texture, and purpose with the same care you put into the concept, so the result doesn’t feel mass-produced, but intentional — something that belongs there, and feels right the moment you step back and look at it.

Interestingly, many of our clients say that our products in the room capture the expression of stone, the warmth of wood, or the airy look of coral even more convincingly than the materials themselves. At the same time, foam is lighter, easier to work with, durable, and capable of bringing even the most complex design ideas to life.

Every custom project goes through several stages — a mix of creative development and technical refinement. With bespoke elements, the small things matter. Every detail counts. That’s the only way to achieve a result that installs smoothly and delivers the impact you want.

This is exactly what happens at Royal Foam: ideas don’t stay concepts — they take shape.

Custom Is the Only Standard We Work With

Most projects don’t fit a template, so we don’t try to push them into one. We start fresh and shape the build around what you actually need. If you have specific dimensions, profiles, colors, or finishes — we focus on getting those right, not “close enough.”

Some designs (for example for ceiling or balcony) lean modern with clean, sharp lines. Others call for traditional detailing. We adjust the material and the production approach to suit the style, not fight it.

Our coatings aren’t generic top layers. They’re made to read and feel like the material you’re aiming for when you see it up close. Coral stone with warmth, concrete that looks like it’s aged naturally, or a woodgrain with a hand-touched character — we can get there without the usual drawbacks of the originals.

If your idea isn’t something that exists yet, that’s fine — we’ll sort out the material makeup, reinforcement, and finish so it holds up in real use, not just in a rendering.

No catalog shortcuts. No “standard options.” Just solutions built around your project and the level of quality you expect to see on site.

We manufacture a wide range of architectural elements that enhance both the structural expression of a building and its visual identity. Our collection includes arches and keystones — a strong choice for bold, Gothic-inspired concepts with arches, keystones or even storybook, castle-like designs.

You’ll also find architectural columns, balustrades and moldings, or even a coffered ceiling — elements that instantly add a romantic “Romeo and Juliet” feel or that timeless Old-World European charm.

For projects leaning toward classical or antique-style architecture with coffered ceiling at the room, we offer coffered ceiling systems, along with column capitals and bases that bring authenticity and visual depth. And to complete both residential and commercial façades, our range of cornices provides the finishing touch that ties the architecture together.

We also produce coffered ceiling and room wall moldings, decorative faux-wood beams, ornamental trims and casings, door surrounds, exterior corbels and brackets, pediments, architectural wall niches, and faux brick, faux stone, and faux wood panels — everything needed to create the right atmosphere and distinctive character for your architectural concept. To finish the exterior composition - set for ceiling and fireplace surrounds, louvers, and shutters that harmonize effortlessly with different architectural styles.

For outdoor environments, community settings, and branding-focused projects, we create monument signs, sills and bands, rustic style stucco fences, stucco mailboxes and lamp posts in contemporary style, as well as window surrounds.

Whether you’re enhancing a private residence, a commercial building, or a large-scale development, our product range allows you to create a unified and expressive architectural identity in every detail.

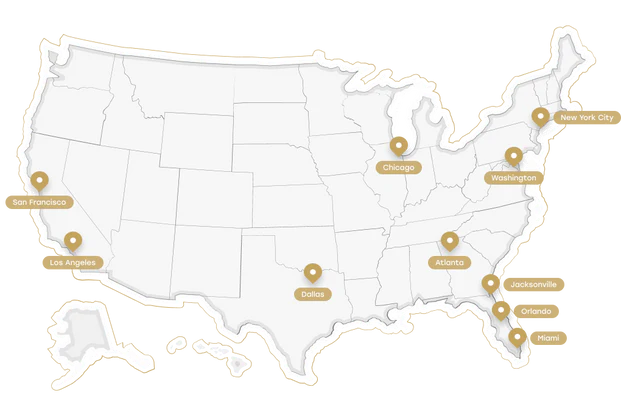

Built for Florida, Proven Everywhere

Operating in Florida means designing for some of the harshest environmental conditions in the U.S. — constant sun, high humidity, heavy rains, and coastal air. Our foam systems are formulated to endure these realities without fading, swelling, or surface degradation. The materials retain their structure and finish under prolonged UV exposure and repeated temperature changes. Because we design for durability in Florida’s climate, our products perform flawlessly anywhere — from tropical resorts to mountain estates. What we build here is built to survive almost anywhere on the map.

Durability You Can Measure and Trust

At Royal Foam, we don’t approach projects as mass production. Each one is treated as a long-term architectural solution — built to last for years, not just a season. Our products aren’t just designed to look unique; they’re engineered to withstand real environmental demands.

We focus on durability from the inside out. Every element is sealed and constructed to resist moisture, impact, and intense sunlight, helping prevent fading, cracking, or surface deterioration. While many exterior coatings lose their color or break down over time, we use high-performance finishes designed to retain their appearance for decades — not just a few years.

Our 20-year warranty isn’t a marketing slogan. It reflects the testing, material selection, and quality control behind every product we deliver — and the responsibility we take for its performance.

A Royal Foam project gives you confidence: confidence that the architectural details you choose will hold their look, their strength, and their value for the long run.

Design Freedom Without Compromise

We work directly with architects, builders, and design teams to translate ideas into precise, buildable solutions. Decorative façades, signage, exterior molding, full perimeter systems — whatever the scope, each piece is made to fit your design language and installation needs.

Textures, tones, dimensions: consistent from the first sketch to the final install. You keep creative control, without losing structural clarity, timing, or visual unity.

At Royal Foam, we’re not here for one-off orders. We focus on long-term design partnerships. What we produce has a simple purpose: to function, to hold its aesthetic, and to last.

Time-Tested Reliability

For over a quarter of a century, we have been creating architectural solutions that combine tradition with modern technology.

Advanced Production

All products are manufactured in full compliance with standards and regulations, with a guaranteed level of quality.

Custom Solutions

We bring any design idea to life — from unique shapes to fully customized projects tailored to your needs.

Full Support

We handle the entire process — from development and technical documentation to organizing transportation.

Who Is This Solution For?

-

Home Associations — Increase visual house appeal, strengthen community identity, and enhance property value with long-lasting, architectural exterior elements that create a polished and welcoming impression.

-

Architects — Elevate your design concepts of rooms and houses with refined, detail-driven accents that add structure, balance, and signature style to any architectural project.

-

Builders — Deliver distinctive aesthetics and durable, construction-grade quality that elevate your projects and attract higher-value buyers and tenants.

-

Homeowners — Give your exterior a unique, tailored look that reflects your style and leaves a lasting impression.

Give Your Space a Signature Look with Custom 3D Accents and Branding

We are your full-service resource for 3D exterior advertising, commercial and residential signage, and architectural accents that instantly capture attention. Dimensional signage is the first visual touchpoint for anyone approaching your establishment — make sure it communicates professionalism, credibility, and style from the very first glance.

Our hand-crafted 3D advertising products offer elevated design, strong brand recognition, and premium curb appeal that distinguishes your property, business, or community from the rest.

Why Choose Us

Engineered and Manufactured in the USA

All Royal Foam systems are manufactured in the United States with consistent oversight and attention to detail. Our team ensures that each product meets quality standards, making adjustments when necessary to achieve the expected result.

For us, design defines the space, and we align each project with the intended tone and character.

We don’t treat your order as just another number in a long queue. Each project receives careful, individual attention from the beginning, landing on the desk of a specific project manager — someone who cares about the details and the outcome, and about how well the final result reflects your vision.

If something in your sketches, drawings, or explanations isn’t clear, we ask questions, because that’s what ensures a successful result. We focus on details that many overlook (or notice only when it’s already too late). Color matching, attachment points, how multiple elements connect into one architectural piece, the installation environment, the climate the product will be exposed to — all of it matters.

These nuances are what allow us to deliver a product that performs well and serves you for many years. And when you finally see the finished product in the room, the goal is simple — you feel that quiet, confident “yes, this is exactly what I pictured.”

The aim is simple, but not small: when you see the final result, it should feel right. Not generic. Not stiff or “close enough.” It should fit your project the way a well-composed melody fits the ear — naturally, effortlessly, and with a sense of “yes, that’s exactly right”. And if we manage to give you more than you asked for - in a way that pleasantly surprises you - that’s a win for us. We take the time to select the right shade, refine the texture, and sculpt the profile so it feels purposeful and perfectly in tune with your vision.

What you receive is more than a product — it’s a considered design element that brings warmth, character, and visual harmony to a space. It captures the elegance of natural materials, yet spares you their weight, upkeep, and performance drawbacks.

It’s an aesthetic that doesn’t just look exceptional on day one — it continues to inspire, uplift, and endure for years to come.

System Integration by Design

Our products are developed as a cohesive system. Fencing, columns, caps, and trim share the same materials, textures, and tones, ensuring a unified architectural result rather than competing elements.

What you get is a look that feels intentional from the curb to the closest detail. No visual noise, no “why doesn’t that match?”, just a seamless presentation that elevates the space and makes your design look as thought-through as it truly is. It’s the kind of cohesion clients may not always be able to explain — but they notice it immediately.

Coordinated Logistics Support

Material deliveries have a bad habit of showing up either too early or too late — and both create chaos on site. We get that. That’s why Royal Foam stays actively involved in the logistics, not just “on the email thread.”

We coordinate with your installation team and the transport company to confirm the schedule and ensure that delivery happens at the right time—when it benefits you and without compromising the quality of the products you ordered.

The goal is practical, not poetic: your materials arrive when your crew can actually use them, not when they become a burden. Less waiting. Fewer bottlenecks. No pallets sitting in the mud for a week.

Whether it’s access windows, on-site storage limits, or the order in which materials need to hit the ground, we shape the delivery plan around your reality — so materials show up when they should, where they should, and ready for the next step. The result is a smoother project timeline with fewer delays and a prepared site on arrival.

Precision-Led Installation Performance

Installation efficiency has a direct impact on labor allocation, sequencing, and total project cost. Engineered dimensional accuracy and consistent fabrication minimize field modification and alignment correction, resulting in accelerated schedules and more cost-efficient closeouts.

Our Non-Negotiables

We maintain two strict requirements on every project: precise plumb alignment and accurate color consistency. When those are in place, the system functions and presents the way it was meant to.