Elegant Details for Every Design

Enhance your interiors and exteriors with our Decorative Trims — the perfect blend of beauty and functionality. Crafted from premium EPS with a protective hard coating, they offer the classic look of plaster or stone without the weight or cost. Easy to install and weather-resistant, our trims bring refined detail and lasting elegance to any architectural design. Discover how simple it is to achieve a luxurious finish that stands the test of time.

Companies We Serve

Precision Meets Timeless Style

Add character and depth to your project with our Decorative Trims, designed for precision, durability, and style. Made from lightweight, high-density materials, they’re built to resist moisture, UV rays, and impact while maintaining a flawless appearance. Whether framing windows, doors, or ceilings, these trims provide the perfect finishing touch for modern and traditional designs alike. Elevate your space with architectural detail that inspires.

Who Is This Solution For?

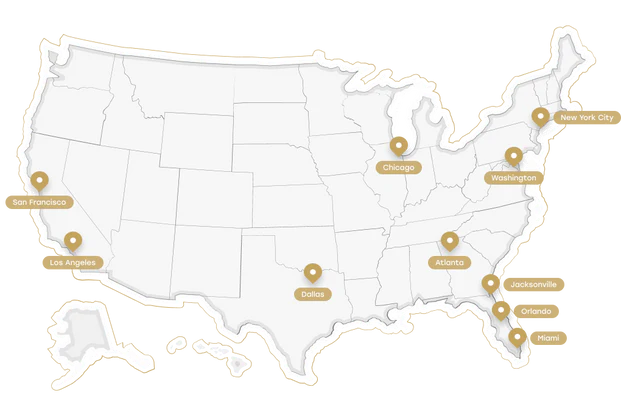

Areas We Service

We proudly serve clients across the United States, including major cities such as

USA: · Jacksonville · Orlando · Miami · Atlanta · Dallas · Los Angeles · New York City · Chicago · Washington · San Francisco ·

How to Order From Royal Foam

Step 1. Ready design

If you have a finished project, we adapt it for production and installation, preserving every detail.

Step 2. Define your vision

Capture a clear picture of the client’s ideas before moving to design and rendering.

Step 3. Plan specifications

Outline measurements, production methods, and finalize materials, components, and finishes.

Step 4. Installation

Our team ensures precise setup, perfectly aligning your custom surround with the space.

Step 1

The aim of this step is to capture a precise picture of the client’s vision before proceeding to technical design and visual rendering.

Step 2

During this phase, we define the specifications, production methods, and measurements, while finalizing the look by selecting materials, elements, and finishes.

Step 3

Once fabrication is complete, our installation team will handle every aspect of the setup, ensuring your custom surround is fitted with accuracy and seamlessly integrated into your space.

More Categories

· Window Surround · Door Surround · Architectural Arcades · Custom Architectural Balustrades · Custom Coffered Ceilings · Stucco fence or stucco wall · Exterior Shutters · Custom Architectural Column · Architectural Trims & Mouldings · Architectural Brackets & Corbels · Custom Architectural Arches · Architectural Mailboxes & Mailbox Covers · Custom Architectural Column Caps · Pediments · Architectural Keystones · Custom Architectural Fireplaces · Lamp Posts · Wall Niches · Cornices · Louvers · Wedding Arch & Colonnades · 3D Stage Props & Sculpture Enlargement · Sandblasted Signs · Monument Signs · Routed Signs · 3D Huge Lettering & Logo · Designs for Places of Worship · Crown Moldings · Decorative Foam Sills · Decorative Moldings · Decorative Trims ·

Testimonials

I highly recommend the services of Royal Foam because they are always consistent with their quality of 3D letterings and other products.

Samuel Ridge

Thank You Royal Foam for providing me with the gorgeously designed monument sign I had ordered for my newly opened company.

Danial Bryan

After installing an arch from Royal Foam not only the look has improved but also my home has become a lot more spacious. I suggest and thank Royal Foam. I will contact again to Royal foam for my new arch work at my home. Designs are very good and finishing is also good.

Amy Corey

I had ordered plastic letters to put up in front of my Company and I’m thanks to the quality, come rain or sun, they shine like new always. Thank you for such good products Royal Foam.

Origin Teak

Frequently Asked Questions

Blog posts

-

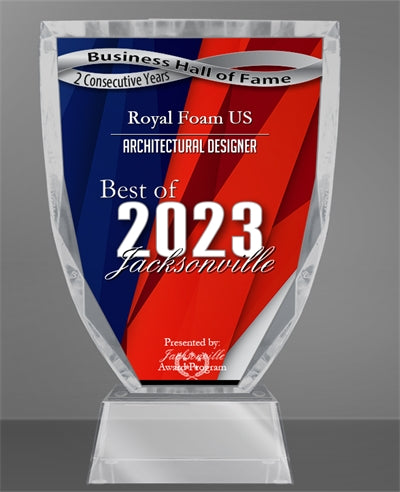

Royal Foam US Receives 2023 Best of Jacksonville Award

Read nowPress Release FOR IMMEDIATE RELEASE Royal Foam US Receives 2023 Best of Jacksonville Award Jacksonville Award Program Honors the Achievement JACKSONVILLE April 20, 2023 -- Royal Foam US has been selected for the 2023 Best of Jacksonville Award in the...

-

-

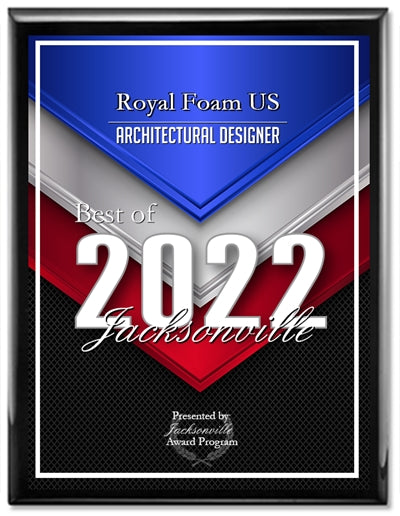

2022 Best of Jacksonville Award

Read nowPress Release FOR IMMEDIATE RELEASE Royal Foam US Receives 2022 Best of Jacksonville Award Jacksonville Award Program Honors the Achievement JACKSONVILLE August 16, 2022 -- Royal Foam US has been selected for the 2022 Best of Jacksonville Award in the Architectural...

Decorative Trims

Even the most ordinary building facade can be transformed into an example of unusual architectural design without much effort.

For such a metamorphosis, you need decorative trims made of EPS foam. They are lightweight, maintenance-free, and 60% cheaper than traditional materials.

For over 20 years, Royal Foam's revolutionary expanded polystyrene decorative trim line of products has been enhancing residential and commercial buildings across the country with factory-direct prices and unparalleled design freedom. Our wide variety will be appreciated by contractors looking for rapid installation options and homeowners planning their perfect remodel.

Why EPS foam decorative trims are a brand new step in home decoration

Over the past few years, the building industry has witnessed a growing need for products that are not only aesthetically flawless but also efficient. Expanded polystyrene (EPS) perfectly meets these demands with its benefits that conventional trim moldings cannot compete with.

Plaster and wood decorative exterior window trim products are prone to moisture uptake, infestation by pests, and instability in dimensions, resulting in expensive maintenance and replacement cycles. So, understanding the differences between conventional finishing materials and modern foam finishing elements shows why smart builders choose Royal Foam’s solutions.

How EPS foam moldings save time and money

The distinctive feature of expanded polystyrene is its combination of a closed-cell structure and high density. Here's what each of our decorative details looks like in cross-section:

- Expanded polystyrene core

- Protective aromatic urethane coating

- Authentic stucco finish

- High quality paint

Thanks to this design, water does not penetrate architectural details, making them perfect for use outdoors. And a plus: the foam will still retain its dimensional stability even after being subjected to temperature fluctuations. By resisting extreme expansion when heated and contracting when chilled, the material prevents the spotting of gaps, cracks, and flaking paint - problems that are common with traditional decorative window trims.

The unique coating protects parts not only from precipitation but also from UV exposure effects and repels insects, preventing concerns about such damage caused by termites or carpenter ants that ruin wood installations.

The cellular nature of EPS foam trim moulding is as much as 80% lighter in weight compared to equivalent stone or concrete, considerably reducing structural load requirements. This weight reduction has the direct consequence of lower installation cost as well as simpler logistics for high-volume commercial applications.

Fire-resistant formulations meet commercial building codes without compromising workability or finish appearance. Our decorative exterior stucco foam trims are easy to cut and shape using standard woodworking tools, enabling precise on-site adjustments without special equipment.

Installation benefits for tight deadlines

Royal Foam decorative trim is very light in weight and adheres firmly with current building adhesives, eliminating the mechanical fasteners required for heavier alternatives. Adhesive-only installation here creates visually seamless lines while reducing the number of possible failure points built into traditional mounting systems.

Individual installers can install pieces that would otherwise require teams to get done with conventional materials. This reduces labor costs and project time significantly. The absence of pre-drilling, countersinking, and fastener hiding speeds installation and results in a better finished appearance.

Types of decorative trims: for walls and more

There are several options for using architectural trims, each offering a unique way to enhance your space. Here are the most common types.

Wall moldings- Decorative wall moldings are used to add texture to plain walls. The most common options are:

- Chair rails. They divide walls horizontally, protecting them and adding visual interest.

- Picture rails. These are located under the ceiling and serve both a practical and decorative function.

- Ceiling moldings transform the look of any room, adding sophistication to the often overlooked ceiling. The most demanded options include:

- Crown moldings. Installed at the junction of walls and ceilings, they give the room a refined and classic look.

- Ceiling medallions. Ideal for highlighting light fixtures or chandeliers.

- Cornices. Used to hide seams and make the ceiling visually deeper.

- These architectural trims are aimed at making frames around doors and windows more noticeable.

Decorative trim styles: touch of modernity for any era

Our extensive collection has over 40 unique profiles to enhance any traditional revival, contemporary minimalist, or transitional design. Each style category meets some aesthetic and functional requirement without sacrificing the durability and sustainability of today.

Classic and traditional architectural trims

Historical accuracy here meets universal conciseness. The absence of pretentious patterns allows decorative trims to fit into virtually any design: all you have to do is choose.

Greek Revival and Federal style elements are embodied in different types of relief, sharp or smooth. These options fit perfectly into the growing market for traditional American architectural styles.

Victorian cornices, window headers, and door surrounds allow restoration work to maintain historical integrity without the maintenance burden of original materials. Our exterior foam trim molding profiles can include multiple scale options in an effort to offer accurate proportional relationships regardless of building size.

Contemporary and modern design solutions

Our selection of modern exterior stucco foam window trims emphasizes horizontal lines and shadow play, which are appropriate to contemporary design trends.

Simple accent details and linear geometries are particularly suited to commercial buildings, where maintenance ease must be reconciled with the complex visual element. Linear trim pieces create a clean architectural design without dominating building forms.

Transitional styles straddle old and new, offering an option for projects that must satisfy diverse aesthetic preferences while having a consistent architectural character.

Stucco foam trims for specialized regional and cultural adaptations

The local design sensibilities determine the selection of the decorative trim significantly. Royal Foam meets this demand with niche profiles. Our Southwest adobe-style stucco foam window trims exhibit the free-form curves associated with distinctive regional styling.

Southern Colonial details respect the precise heritage of pre-war design. Such high-tech foam trim molding solutions allow builders to create authentic regional character without sacrificing today's performance demands.

Strategic stucco foam trim application in various building types

Effective decorative molding installation relies on the material's properties meeting specific application requirements. Royal Foam’s expanded polystyrene (EPS) solutions are optimal for diverse project types, from intimate residential renovations to large-scale commercial developments.

Residential remodeling and renovation projects

To homeowners' delight, decorative stucco foam trim transforms bland builder-grade construction into unique, personalized architecture. Exterior applications include door and window casings, corner units, foundation skirts, and roofline accents that greatly improve curb appeal and property values.

Interior applications include crown molding alternatives, chair rails, and decorative wall panels that offer refined detail without the installation inconvenience of traditional plasterwork. Since all Royal Foam’s products are prefabricated, homeowners can customize the color scheme of the details to match their project.

Renovation efforts particularly benefit from foam window trim's weight savings, given that old buildings do not necessarily have the capacity to support the increased load of heavy traditional material. Dimensional stability ensures new installations will not shift or become loose against adjoining building components.

Commercial and institutional building molding solutions

Large-volume commercial projects demand materials that strike a balance between visual attraction, functional performance, and cost awareness. Office complexes, shopping centers, and hotel properties make use of Royal Foam's exterior stucco foam trim to create distinctive facades while meeting tight budgetary goals.

The fire-resistant options are suitable for commercial building codes, and lightweight properties reduce structural requirements. All of these contribute to great cost savings on larger projects when typical materials require more structural support.

Hospitals and schools appreciate the lack of maintenance, which translates to no downtime. Pest resistance assures longevity in situations where typical materials could harbor unwanted organisms.

Historic preservation and restoration use

Where to buy stucco foam trim for restoration is a vital issue when the use of both authenticity and performance is necessary in projects. Our ability to replicate profiles historically with accuracy allows you to restore original looks and provide increased durability and maintenance features.

Three-dimensional scanning and CNC replication capabilities ensure that replacement elements match the original details precisely, maintaining historical accuracy and providing superior long-term performance. The lightweight construction reduces stress on aging structural systems, helping to preserve overall building integrity.

Royal Foam's direct manufacturing approach ensures the availability of specialized profiles that commercial distributors cannot economically stock.

That’s why Royal Foam is the best choice when it comes to decorative trim

20+ years of specialized experience

20+ years of specialized experience in architectural foam manufacturing sets Royal Foam apart from general building material distributors. Our Jacksonville facility combines traditional craftsmanship with modern CNC technology to deliver precision-cut decorative moldings and other elements with consistent quality.

Factory-direct pricing and custom capabilities

Eliminating distributor markups while maintaining quality control at every production stage provides exceptional value to customers. Our integrated approach covers everything from initial design consultation to final delivery, offering single-source accountability that streamlines project management.

Rapid prototyping and custom profile development capabilities serve projects requiring unique architectural elements. Whether recreating historical details or developing contemporary accent pieces, our design team works directly with architects and builders to achieve authentic results.

Custom manufacturing processes include detailed drawings, material specifications, and installation guidance that provide complete project support from concept to completion.

Technical support and installation resources

Professional installation support includes technical specifications, adhesive recommendations, and troubleshooting guides to ensure a successful project outcome. Our highly qualified team understands the unique requirements of different climate zones and building types.

Detailed installation manuals and video resources help contractors optimize their procedures, avoiding common mistakes that can affect performance or appearance. This support infrastructure reflects our commitment to customer success beyond the initial sale.